Discover Top-Quality Hydraulic Pumps and Motors from Leading Chinese Manufacturers

In the realm of industrial machinery, the performance and reliability of Hydraulic Pumps and Motors play a pivotal role in ensuring efficient operations. As industries increasingly seek to enhance productivity and reduce costs, the demand for high-quality hydraulic components has surged. Leading Chinese manufacturers have risen to meet this demand, offering a diverse range of hydraulic pumps and motors that excel in both durability and performance. This tutorial will guide you through the top options available on the market, providing insights into their specifications, applications, and the key features that set them apart. Whether you are an engineer, a procurement officer, or simply an enthusiast, understanding the offerings from these manufacturers will empower you to make informed decisions and drive your projects to success. Join us as we delve into the world of hydraulic technology and discover the best solutions to elevate your operations.

The Importance of Compliance with International Production Standards in Hydraulic Products

In the rapidly evolving world of hydraulic products, compliance with international production standards is not merely a regulatory requirement; it is a critical factor that ensures safety, reliability, and performance. Leading Chinese manufacturers are increasingly focusing on adhering to these standards, recognizing that adherence not only enhances product quality but also builds trust with international customers. By meeting standards set by organizations such as ISO and SAE, manufacturers demonstrate their commitment to producing hydraulic pumps and motors that can withstand rigorous operating conditions and deliver optimum performance.

Moreover, compliance with international standards allows manufacturers to tap into global markets more effectively. When products are certified and meet the stringent requirements of various regions, they can be more readily accepted by industries such as construction, agriculture, and automotive. This global perspective pushes manufacturers to innovate continually and improve their processes, ensuring that their products are not only competitive in terms of cost but also in quality. As customers increasingly seek reliable and efficient hydraulic systems, the focus on compliance and quality assurance will define the future landscape of hydraulic manufacturing.

Discover Top-Quality Hydraulic Pumps and Motors from Leading Chinese Manufacturers

| Product Type |

Flow Rate (L/min) |

Max Pressure (bar) |

Motor Power (kW) |

Weight (kg) |

Compliance Standards |

| Gear Pump |

45 |

250 |

5.5 |

25 |

ISO 9001, CE |

| Hydraulic Motor |

60 |

210 |

7.5 |

30 |

ISO 14001, CE |

| Piston Pump |

80 |

300 |

11 |

40 |

API, CE |

| Vane Pump |

35 |

180 |

4 |

20 |

ISO 9001, RoHS |

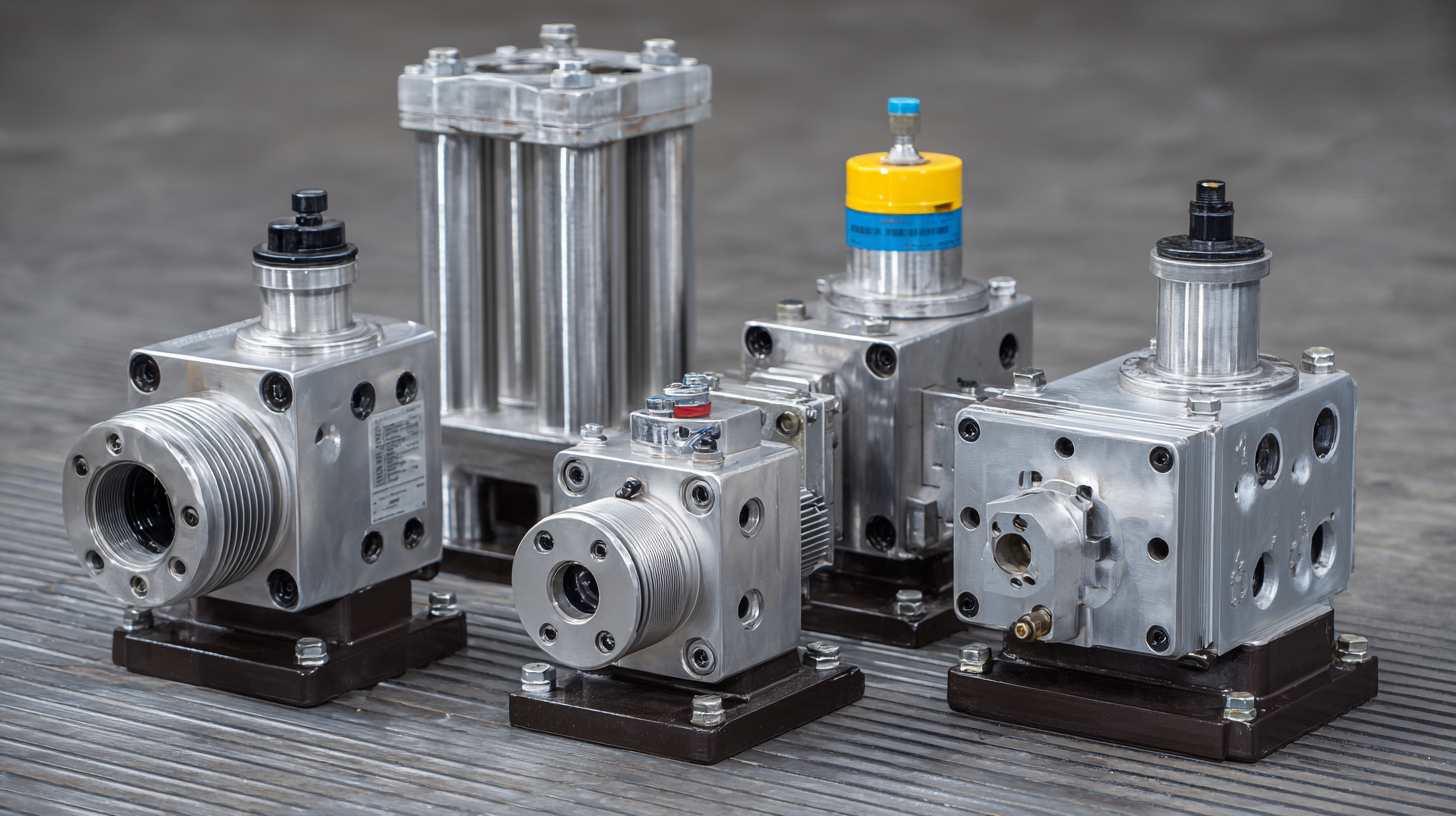

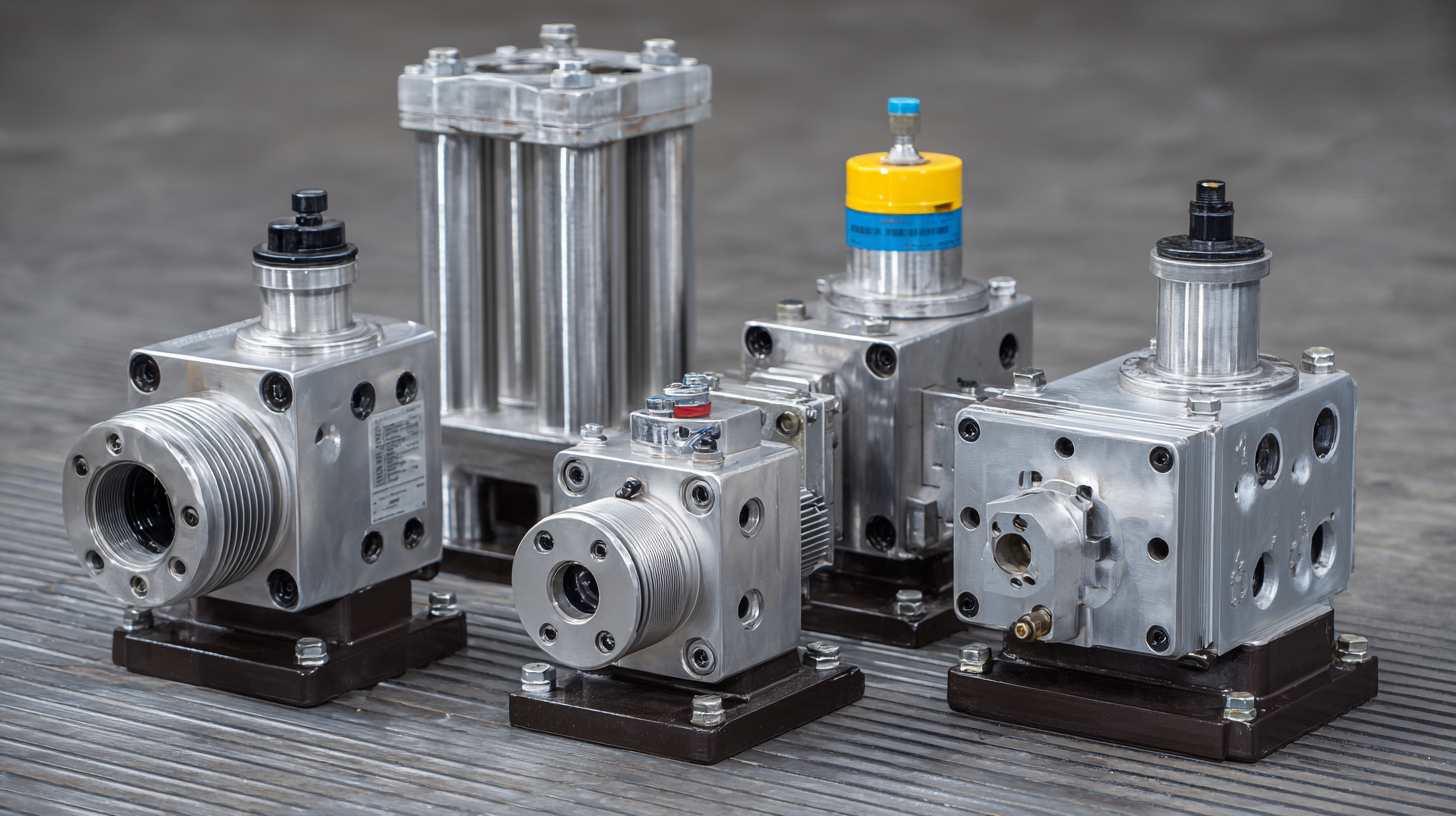

Key Features of High-Quality Hydraulic Pumps and Motors from Leading Chinese Brands

When exploring high-quality hydraulic pumps and motors, it's essential to identify the key features that distinguish leading Chinese manufacturers in this competitive market. According to a recent report by Market Research Future, the global hydraulic pump market is projected to reach over $15 billion by 2025, with the Asia-Pacific region accounting for a significant share of this growth. This burgeoning demand highlights the importance of understanding what sets top-tier hydraulic technology apart.

Leading Chinese brands are renowned for their robust designs, advanced materials, and innovative technologies. These hydraulic pumps and motors often feature high efficiency ratings and long operational lifespans, making them ideal for various applications, from construction machinery to industrial automation. Furthermore, data from the Hydraulic Institute illustrates that products that meet or exceed international standards not only ensure reliability but also enhance performance, contributing to increased productivity and decreased downtime in operational settings. Thus, investing in these premium products is a strategic choice for businesses aiming to optimize their hydraulic systems.

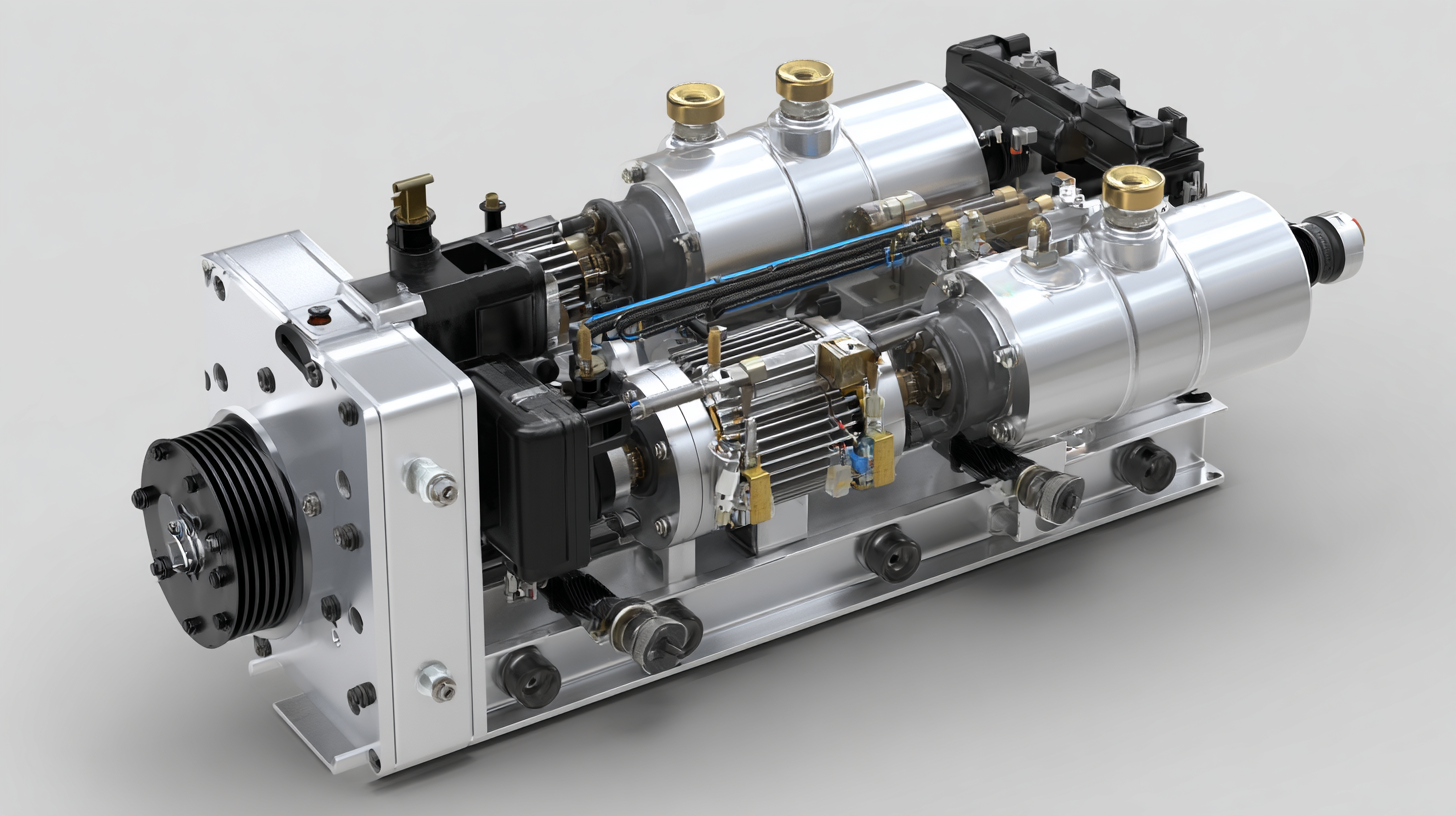

Impact of Technological Advancements on Hydraulic Equipment Manufacturing Standards

Technological advancements have significantly transformed the hydraulic equipment manufacturing landscape, enhancing the quality and efficiency of hydraulic pumps and motors produced by leading Chinese manufacturers. Innovations in materials, design software, and production techniques have allowed manufacturers to create more durable and reliable products that meet the increasing demands of diverse industries. Modern hydraulic equipment now features improved energy efficiency and reduced operational noise, driven by advanced engineering and precision manufacturing processes.

Tip: When selecting hydraulic pumps and motors, always consider the technological specifications provided by the manufacturer. Look for products that highlight recent technological improvements, as these often ensure better performance and longevity.

Moreover, the integration of automation and smart technology in hydraulic systems has led to refined manufacturing standards. Many manufacturers are now leveraging IoT capabilities to offer real-time monitoring of equipment performance, which not only improves maintenance practices but also enhances overall operational efficiency. With a robust response to market demands, Chinese manufacturers continue to push the envelope in hydraulic technology.

Tip: Regularly assess the capabilities of hydraulic equipment to ensure it aligns with the latest technological standards. This practice guarantees that your operations remain competitive and that you're utilizing the most advanced solutions available.

Comparative Analysis of Chinese Hydraulic Products with Global Industry Standards

The hydraulic pump and motor industry in China has experienced significant structural changes, as evidenced by the recent customs data indicating a surge in both imports and exports. This shift highlights the increasing competitiveness of Chinese hydraulic products against global industry standards. As the market continues to expand, major Chinese manufacturers are now not only meeting domestic demands but also gaining recognition on the international stage.

An essential factor contributing to China's standing in the hydraulic industry is the establishment of national standards that align with global benchmarks. Recent approvals for new standards are paving the way for enhanced quality assurance and efficiency in production. This initiative aims to fill existing gaps in the standardization process, ensuring that Chinese hydraulic products are not only robust but also compliant with international specifications. Consequently, this will bolster the reputation of Chinese manufacturers, enabling them to compete more effectively on a global scale.

In summary, the comparative analysis of Chinese hydraulic products reveals a promising trajectory, where advancements in technology, adherence to global standards, and strategic market positioning are facilitating China's rise as a key player in the hydraulic sector. As the industry evolves, it is poised to play an increasingly critical role in various sectors, including construction, agriculture, and manufacturing.

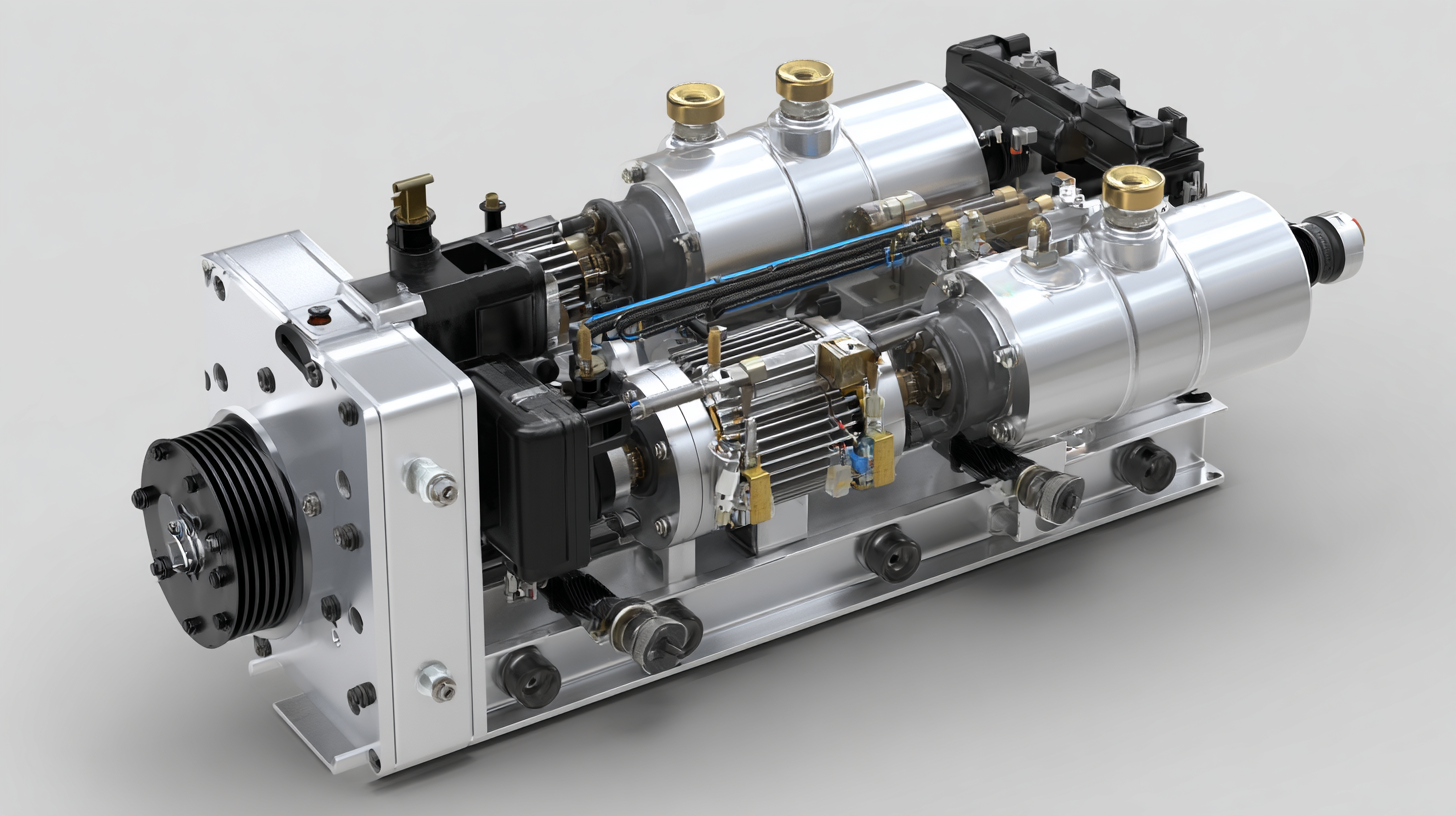

Future Trends in Hydraulic Pump and Motor Production: Standards and Innovations

In recent years, the hydraulic pump and motor industry has witnessed significant advancements driven by innovations and the necessity for higher production standards. According to a report by the International Hydraulic Industry Association, the global hydraulic pump market is projected to reach $18 billion by 2025, with a compound annual growth rate (CAGR) of approximately 5.2%. This growth is fueled by increasing demand from sectors such as construction, agriculture, and manufacturing, where efficient and reliable hydraulic systems are vital.

One of the major trends shaping the future of hydraulic pump and motor production is the integration of smart technology and IoT. Manufacturers are now leveraging these technologies to enhance the efficiency and longevity of their products. For instance, a study by Research and Markets highlights that the adoption of IoT in hydraulic systems can lead to a 30% reduction in maintenance costs through predictive analytics. Additionally, sustainability is becoming a pivotal focus, with many leading Chinese manufacturers shifting towards eco-friendly materials and energy-efficient designs to comply with global environmental standards and consumer demand for greener products.

Hydraulic Pumps and Motors Production Trends (2023)