Revolutionizing Industries: Real-World Applications of the Best Hydraulic Pump Systems

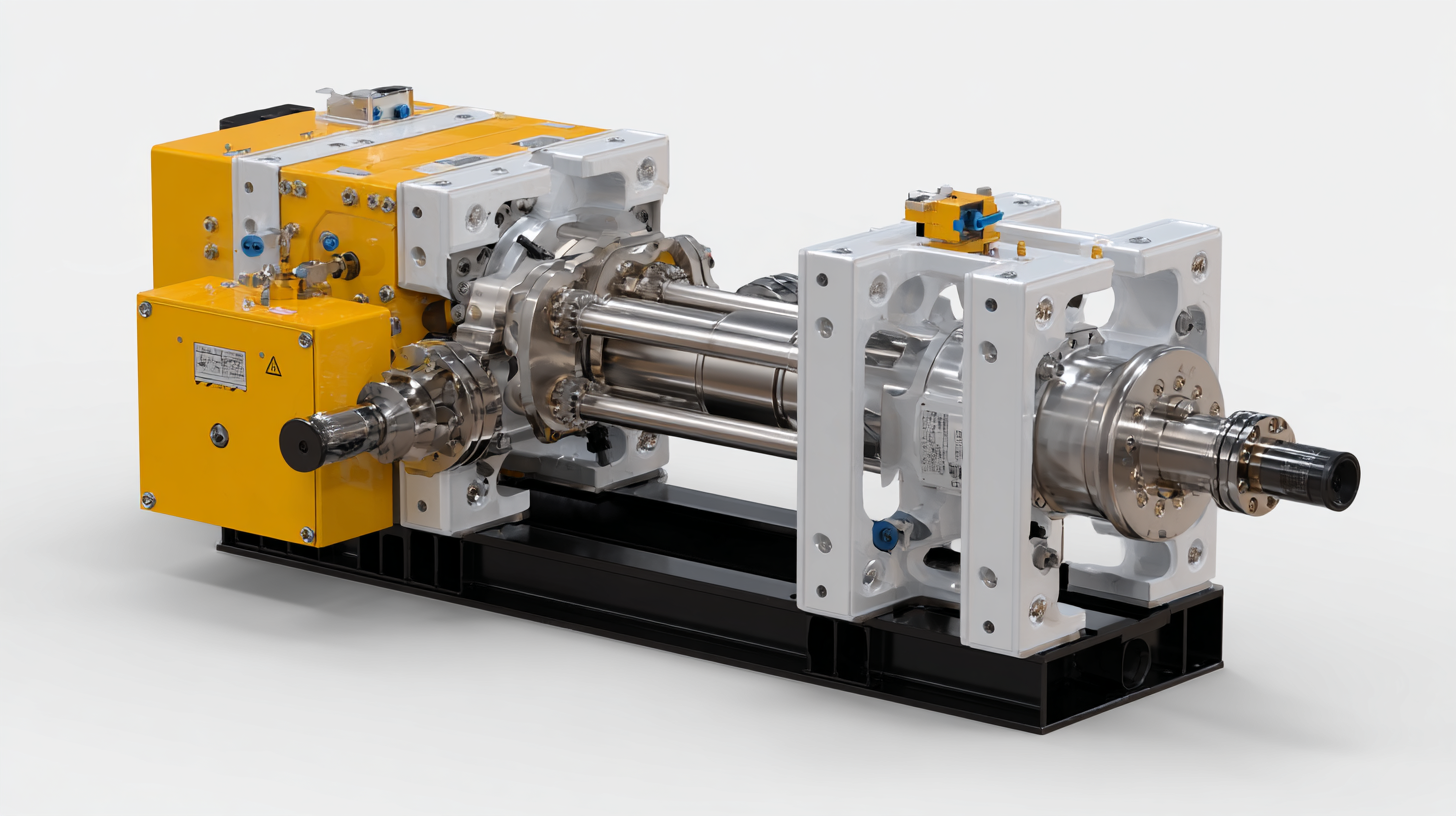

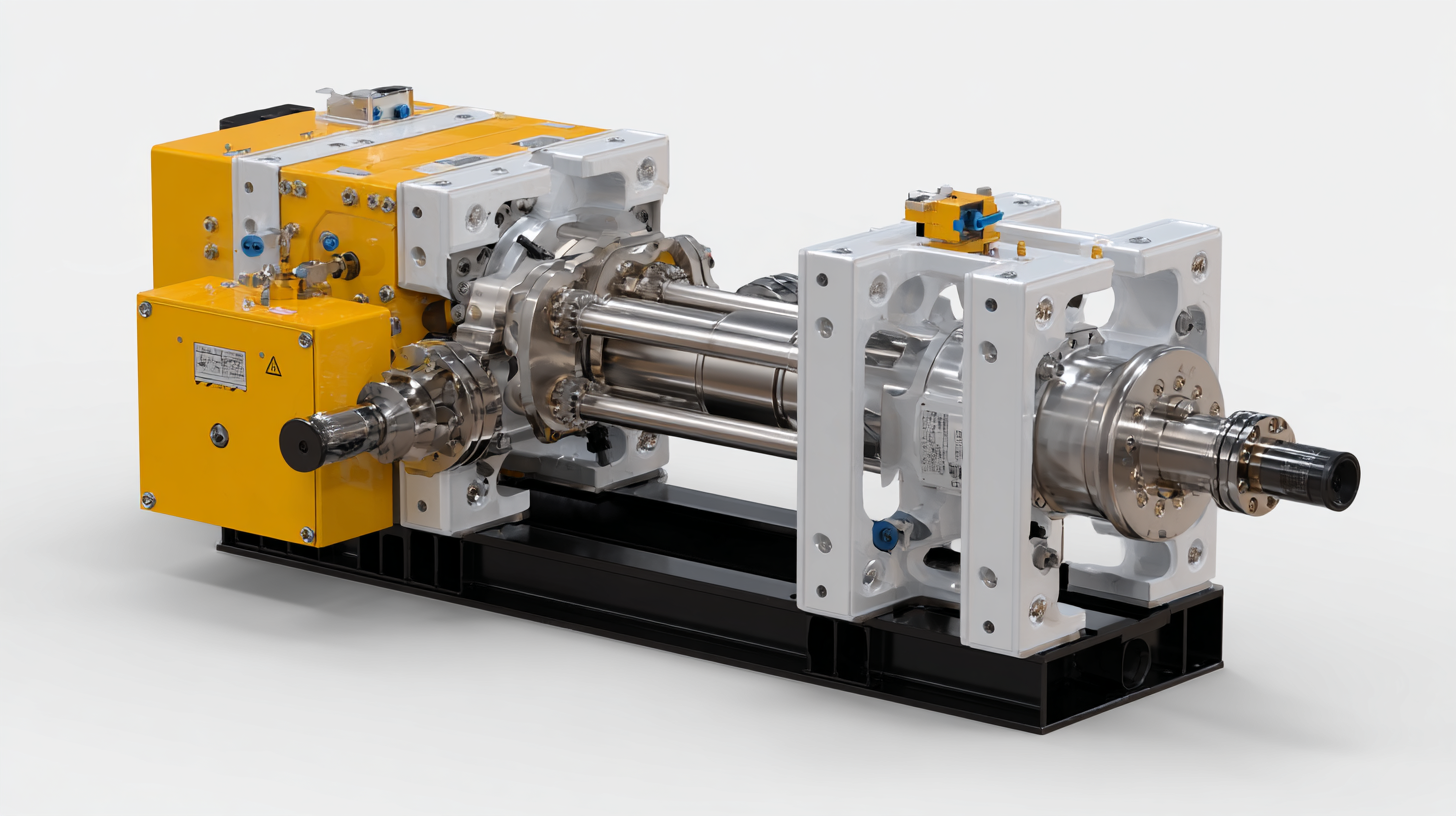

In today's rapidly evolving industrial landscape, the significance of efficient and powerful machinery cannot be overstated. Among these, the Hydraulic Pump System stands out as a pivotal technology driving innovation across various sectors. From construction and manufacturing to agriculture and automotive industries, hydraulic pumps are essential for facilitating complex processes that require precise control and high lifting capability.

As we delve into the real-world applications of the best hydraulic pump systems, it becomes evident how they are revolutionizing industries by enhancing productivity, reducing labor costs, and improving safety measures. This blog aims to explore the cutting-edge advancements in hydraulic pump technology and their transformative impact on modern industries, showcasing how businesses leverage these robust systems to achieve greater operational efficiencies.

Join us as we uncover the remarkable ways hydraulic pump systems are shaping the future of industry.

As we delve into the real-world applications of the best hydraulic pump systems, it becomes evident how they are revolutionizing industries by enhancing productivity, reducing labor costs, and improving safety measures. This blog aims to explore the cutting-edge advancements in hydraulic pump technology and their transformative impact on modern industries, showcasing how businesses leverage these robust systems to achieve greater operational efficiencies.

Join us as we uncover the remarkable ways hydraulic pump systems are shaping the future of industry.

The Transformative Impact of Hydraulic Pump Systems on Manufacturing Efficiency

Hydraulic pump systems have become pivotal in enhancing manufacturing efficiency across various industries. According to a report by the International Journal of Advanced Manufacturing Technology, the integration of advanced hydraulic systems can lead to a 30% increase in operational efficiency. This significant improvement is primarily attributed to the precision and reliability these systems offer, enabling manufacturers to optimize production processes and reduce downtime. By utilizing high-quality hydraulic pumps, companies can achieve smoother operations, ultimately resulting in increased throughput and lower operational costs.

**Tips**: To maximize the benefits of hydraulic systems, companies should consider regular maintenance schedules. Ensuring that pumps are well-maintained not only extends their lifespan but also prevents costly breakdowns and production halts. Additionally, investing in smart hydraulic systems with integrated sensors can provide real-time feedback, further enhancing efficiency by allowing for proactive adjustments based on operational data.

The transformative impact of hydraulic pump systems doesn't end at efficiency. A study published by the Hydraulic Institute highlights that these systems can significantly reduce energy consumption by up to 25%. This reduction is crucial as manufacturers strive for sustainability, aligning with global efforts to minimize environmental footprints. Implementing energy-efficient hydraulic systems not only benefits the bottom line but also supports corporate sustainability goals.

**Tips**: Consider evaluating your hydraulic system’s energy consumption regularly. Upgrading to variable displacement pumps can yield substantial energy savings while maintaining the required power output for your applications.

Impact of Hydraulic Pump Systems on Manufacturing Efficiency

Innovative Hydraulic Solutions Enhancing Renewable Energy Production

The advancement of hydraulic pump systems has brought significant transformations to various industries, particularly in the realm of renewable energy. These innovative hydraulic solutions play a crucial role in enhancing the efficiency and effectiveness of energy production systems, such as wind and solar power. By utilizing high-performance hydraulic pumps, energy producers can optimize the operation of turbines and solar tracking systems, ensuring maximum energy capture and reliability under different environmental conditions.

Furthermore, the integration of hydraulic systems into renewable energy infrastructures allows for improved energy distribution and storage solutions. For instance, hydraulic pumps are increasingly being employed in energy-intensive processes like hydroelectric plants, where water pressure can be effectively converted into renewable energy. This not only boosts energy output but also minimizes waste, aligning with global sustainability goals. Through these real-world applications, hydraulic pump systems are revolutionizing how we approach renewable energy production, paving the way for a cleaner, more sustainable future.

Case Studies: Hydraulic Pump Applications in Construction and Heavy Machinery

Hydraulic pump systems have become indispensable in modern construction and heavy machinery, significantly enhancing efficiency and productivity across various applications.

One prominent case study is in the operation of excavators, where hydraulic pumps enable precise control over the movement of arms and buckets. By converting hydraulic energy into mechanical power, these pumps allow for smooth and powerful dig cycles, even in tough terrains. This capability not only speeds up project timelines but also improves operator safety and accuracy, leading to better overall project outcomes.

Another illustrative example can be found in the use of hydraulic pumps in concrete mixers. These systems are designed to manage the flow of concrete, ensuring a steady and uniform mix is delivered where needed. The hydraulic pump's reliability and power allow mixers to perform effectively under demanding conditions, which is critical in large-scale construction projects. This application highlights how hydraulic technology optimizes processes, reduces manual labor, and ultimately contributes to higher-quality construction results. As industries continue to innovate, the significance of hydraulic pump systems remains evident in driving operational advancements.

Understanding the Market Trends and Growth Projections for Hydraulic Pump Technologies

The hydraulic pump systems market has been experiencing significant growth, driven by advancements in technology and the increasing demand for efficient machinery across various industries. In sectors such as construction, agriculture, and manufacturing, the reliance on hydraulic systems for power transmission and control has surged, showcasing their effectiveness in enhancing productivity. With innovations such as variable displacement pumps and energy-efficient designs entering the market, companies are now able to achieve greater performance while minimizing energy consumption and operational costs.

As the industry adapts to shifting market trends, several key factors are influencing growth projections for hydraulic pump technologies. The rise of automation and the integration of smart technologies in hydraulic systems are paving the way for more precise control and improved system diagnostics. Furthermore, the global push for sustainability has prompted manufacturers to focus on eco-friendly solutions, including the development of biodegradable hydraulic fluids and recyclable components. The convergence of these trends suggests a promising trajectory for the hydraulic pump market, positioning it as a vital player in the evolving landscape of industrial solutions.

The Role of Hydraulic Pumps in Advancing Agricultural Automation and Sustainability

Hydraulic pumps play a pivotal role in the advancement of agricultural automation and sustainability, driving efficiencies that are crucial for modern farming practices. According to a report by MarketsandMarkets, the global hydraulic pump market is projected to reach $21.6 billion by 2026, highlighting the increasing reliance on hydraulic systems in various industries, including agriculture. These pumps enable precise control of machinery, from tractors to automated irrigation systems, optimizing resource use and minimizing waste. For instance, hydraulic systems can improve the efficiency of planting and harvesting operations, which can lead to an increase in crop yields by as much as 20%.

Moreover, hydraulic pumps contribute to sustainability initiatives by facilitating the use of precision farming techniques. According to the Food and Agriculture Organization (FAO), implementing modern technologies in agriculture can reduce water usage by up to 30%, which is critical in regions facing water scarcity. Hydraulic systems enhance the durability and precision of these technologies, allowing farmers to monitor and manage their resources more effectively. As the agricultural sector increasingly embraces automation to meet the challenges of climate change and food security, hydraulic pumps will undoubtedly be at the forefront of these transformative efforts.

Revolutionizing Industries: Real-World Applications of the Best Hydraulic Pump Systems

| Application |

Benefits |

Hydraulic Pump Type |

Operating Pressure (bar) |

Efficiency (%) |

| Irrigation Systems |

Enhanced water management |

Gear Pump |

15-25 |

85 |

| Crop Harvesting |

Increased efficiency and reduced labor |

Piston Pump |

20-30 |

90 |

| Tractor Implements |

Improved multifunctionality |

vane Pump |

30-40 |

88 |

| Livestock Feeding Systems |

Consistent and efficient feeding |

Gear Pump |

15-20 |

80 |

| Greenhouse Automation |

Optimized environmental control |

Piston Pump |

25-35 |

92 |

As we delve into the real-world applications of the best hydraulic pump systems, it becomes evident how they are revolutionizing industries by enhancing productivity, reducing labor costs, and improving safety measures. This blog aims to explore the cutting-edge advancements in hydraulic pump technology and their transformative impact on modern industries, showcasing how businesses leverage these robust systems to achieve greater operational efficiencies.

Join us as we uncover the remarkable ways hydraulic pump systems are shaping the future of industry.

As we delve into the real-world applications of the best hydraulic pump systems, it becomes evident how they are revolutionizing industries by enhancing productivity, reducing labor costs, and improving safety measures. This blog aims to explore the cutting-edge advancements in hydraulic pump technology and their transformative impact on modern industries, showcasing how businesses leverage these robust systems to achieve greater operational efficiencies.

Join us as we uncover the remarkable ways hydraulic pump systems are shaping the future of industry.