Ultimate Handbook for Understanding Hydraulic Motors and Their Applications

In recent years, the global hydraulic motors market has exhibited robust growth, driven by increasing demand across various sectors, including construction, agriculture, and automotive industries. According to a report by Market Research Future, the hydraulic motors market is projected to expand at a CAGR of approximately 5.2% from 2020 to 2027. The versatility and efficiency of hydraulic motors make them a preferred choice for applications requiring high torque and precise speed control, further highlighting their significance in modern machinery and equipment.

As industries continue to evolve, understanding the mechanisms and applications of hydraulic motors becomes increasingly critical for engineers and operators. These powerful components convert hydraulic energy into mechanical energy, powering everything from excavators to conveyor systems. This handbook aims to provide a comprehensive overview of hydraulic motors, exploring their types, operational principles, and practical applications. By delving into the intricacies of hydraulic motors, professionals will be better equipped to leverage these technologies, optimize systems, and drive future innovations in their respective fields.

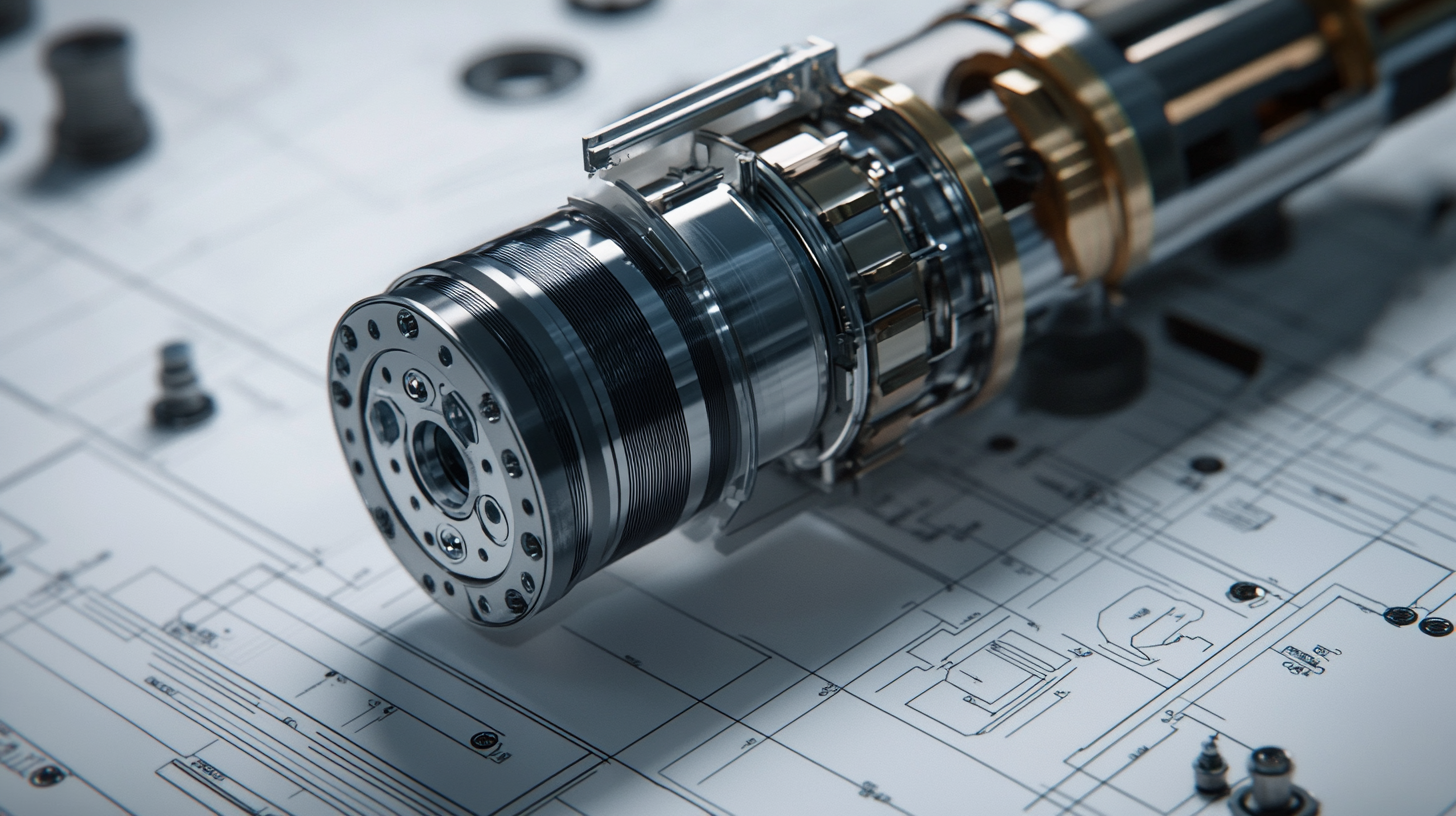

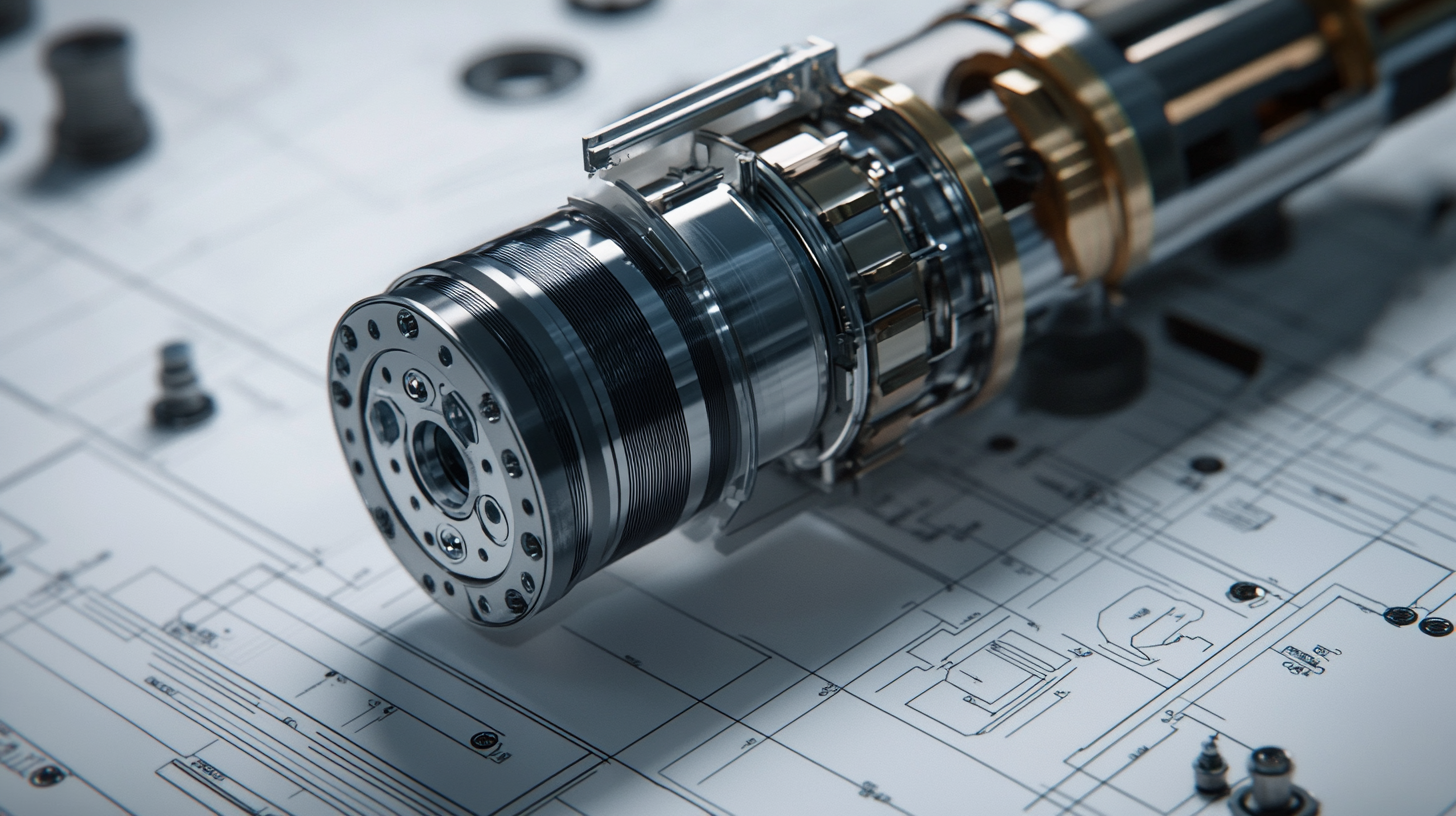

Overview of Hydraulic Motors: Principles and Functionality

Hydraulic motors are pivotal components in a variety of industrial applications, operating on the principle of converting hydraulic energy into mechanical energy. Central to their functionality is the concept of positive displacement, where a fixed amount of fluid is displaced with each cycle. This characteristic enables efficient performance, making hydraulic motors comparable in power density to electric motors, which can be quantified with data indicating that hydraulic systems can deliver torque greater than that of electric equivalents by a factor of three in many fields.

As industries shift towards smarter manufacturing techniques, sensor technologies are becoming integral for monitoring hydraulic valves and system performance. Recent studies highlight that the integration of advanced sensors can reduce maintenance costs by as much as 30% while enhancing the overall reliability of hydraulic systems. The digitalization of hydraulic fluid power systems allows for real-time data acquisition and predictive maintenance, leading to increased operational efficiency.

Moreover, research into magnetic drive pumps suggests a current trend towards enhanced safety and efficiency in fluid handling. These pumps eliminate potential leakage points, thus improving overall system integrity and performance. Statistics from industry reports demonstrate that businesses utilizing such advancements can reduce their environmental footprint significantly while ensuring optimal productivity. As innovations continue to evolve, the importance of understanding hydraulic motors and their applications becomes increasingly critical for staying competitive in the fluid power sector.

Types of Hydraulic Motors: A Comprehensive Comparison

Hydraulic motors play a pivotal role in various industrial applications, primarily known for their ability to convert hydraulic energy into mechanical motion. Understanding the different types of hydraulic motors can help in selecting the right one for specific applications. The two most common types include gear motors and piston motors. Gear motors are popular for their simple design, compact size, and reliability, often used in applications requiring constant torque. On the other hand, piston motors, characterized by their higher efficiency and torque capabilities, are ideal for applications demanding variable speeds and heavy loads.

When comparing these motor types, one notable aspect is their efficiency in energy usage. Recent studies emphasize optimizing power consumption in electro-hydraulic systems through advanced techniques like cylinder bypass and neural network model predictive control (NN-MPC). This approach not only enhances energy efficiency but also improves position control, demonstrating the need to choose the right hydraulic motor based on specific operational requirements.

Additionally, the versatility of hydraulic motors allows their usage in various sectors, from construction and agriculture to renewable energy solutions. For instance, recent evaluations have highlighted the integration of hydraulic motors in off-grid water pumping solutions, illustrating their effectiveness in sustainable energy applications. This adaptability makes hydraulic motors an essential component in optimizing performance across various systems, demonstrating their critical role in modern engineering.

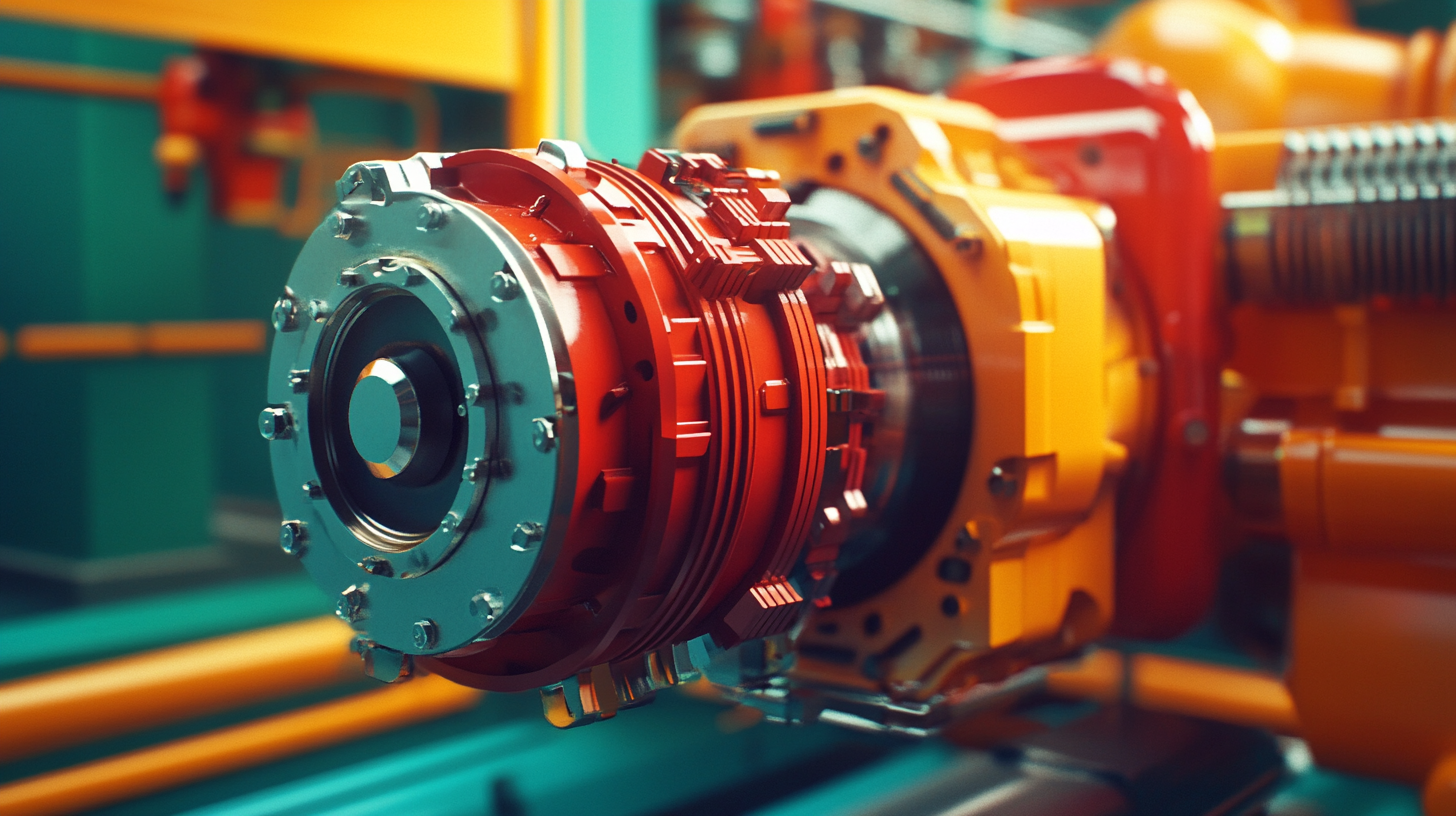

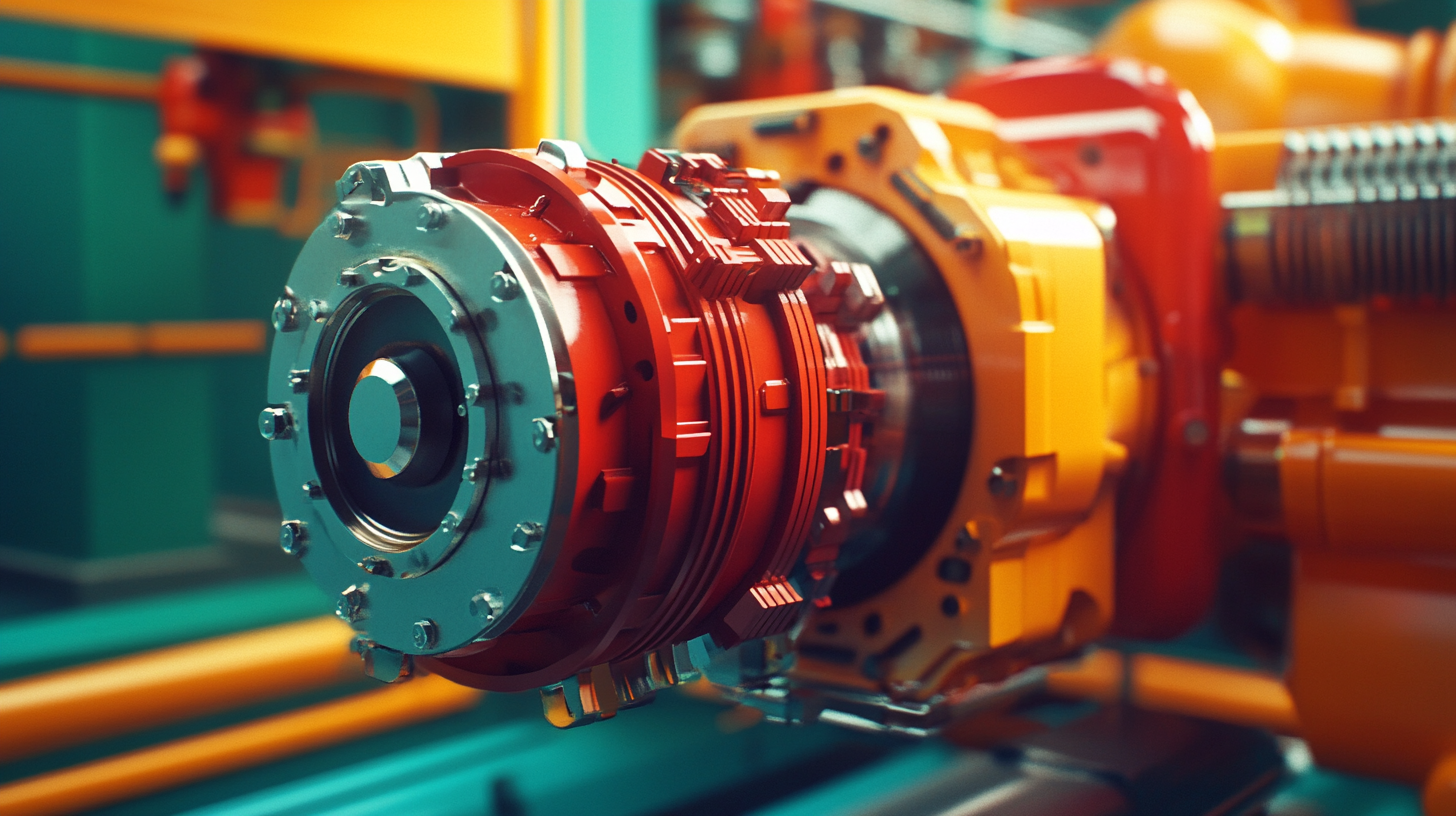

Key Applications of Hydraulic Motors in Various Industries

Hydraulic motors play a pivotal role in various industries, offering powerful performance in applications ranging from construction to manufacturing. In the construction sector, the demand for hydraulic motors has surged, particularly with the increased sales of excavators. These machines rely heavily on hydraulic systems for their operation, showcasing how vital hydraulic motors are in facilitating efficient and effective construction processes. As the industry evolves, domestic manufacturers are stepping up their game, developing core hydraulic components that can match or exceed imported alternatives.

The manufacturing sector also benefits significantly from hydraulic motors, as they drive machinery in processes that require high torque and precision. The recent advancements in China's hydraulic industry, which account for over 30% of the global market share, highlight the growing importance of these components. This growth is indicative of a shift towards more localized production and innovation, as companies innovate to develop integrated testing platforms for hydraulic pumps and motors. Such innovations not only enhance reliability but also improve performance efficiency in various applications.

In addition to construction and manufacturing, sectors like agriculture and mining are increasingly leveraging hydraulic motors for their robust capabilities. With the rise of specialized small and medium enterprises in these fields, the focus on quality and innovation in hydraulic technology is stronger than ever. This burgeoning market underscores the critical applications of hydraulic motors and their potential to transform industry operations, ensuring they remain an essential component for years to come.

Advantages and Limitations of Using Hydraulic Motors

Hydraulic motors are powerful devices that convert hydraulic energy into mechanical energy, offering numerous advantages in various applications. One of the primary benefits of hydraulic motors is their high power-to-weight ratio. This trait allows them to deliver substantial torque while maintaining a relatively compact size, making them ideal for applications where space is limited, such as in construction equipment and agricultural machinery. Moreover, hydraulic motors can operate under extreme conditions, providing reliable performance even in harsh environments, which enhances their durability and service life.

However, despite their advantages, hydraulic motors are not without limitations. One significant drawback is the complexity of the hydraulic system, which often requires maintenance and can incur high initial setup costs. Additionally, hydraulic motors may experience efficiency losses due to heat generated during operation, particularly when running at low speeds. This can lead to increased energy consumption and may necessitate the use of supplemental cooling systems. Therefore, while hydraulic motors are advantageous for numerous heavy-duty applications, careful consideration of their limitations is essential for optimizing performance and operational costs.

Maintenance Tips for Optimal Performance of Hydraulic Motors

Hydraulic motors play a crucial role in various applications, powering everything from industrial machinery to mobile equipment. To ensure these mechanical marvels perform at their best, regular maintenance is essential. One of the most effective ways to extend the lifespan of hydraulic motors is by adhering to a strict maintenance schedule that includes routine inspections and timely oil changes. Checking for fluid cleanliness can prevent contamination, which is one of the leading causes of motor failure.

Moreover, monitoring temperature and pressure levels is vital for optimal performance. Hydraulic motors operate best within specific temperature and pressure ranges. Any deviations from these parameters could lead to overheating or component stress, potentially resulting in system shutdowns or costly repairs. Therefore, it's important to use precision tools to gauge these metrics regularly.

Additionally, inspecting seals and connections for leaks is fundamental in maintaining system integrity. Hydraulic fluid leaks not only waste resources but can also compromise performance. Implementing a proactive approach by replacing worn seals and tightening connections can help mitigate these issues. With proper care and attention to detail, the efficiency and reliability of hydraulic motors can be significantly enhanced, ultimately contributing to better overall system performance.