The Future of Best Hydraulic Pumps and Motors Innovations Transforming Industrial Applications

As we look towards the future, the role of hydraulic pumps and motors in industrial applications is poised for transformation driven by innovative technologies and sustainable practices. By 2025, the market for hydraulic systems is expected to undergo significant changes, influenced by advancements in design, efficiency, and versatility. Industries are increasingly seeking solutions that not only enhance productivity but also reduce environmental impact.

This blog will explore the emerging trends in hydraulic pumps and motors, illustrating how these innovations are set to reshape the landscape of industrial applications. We'll delve into specific examples of cutting-edge technology that exemplify these changes, underscoring their potential to revolutionize operations across various sectors. Join us as we unravel the future possibilities for hydraulic pumps and motors, highlighting their critical role in the evolution of industrial processes.

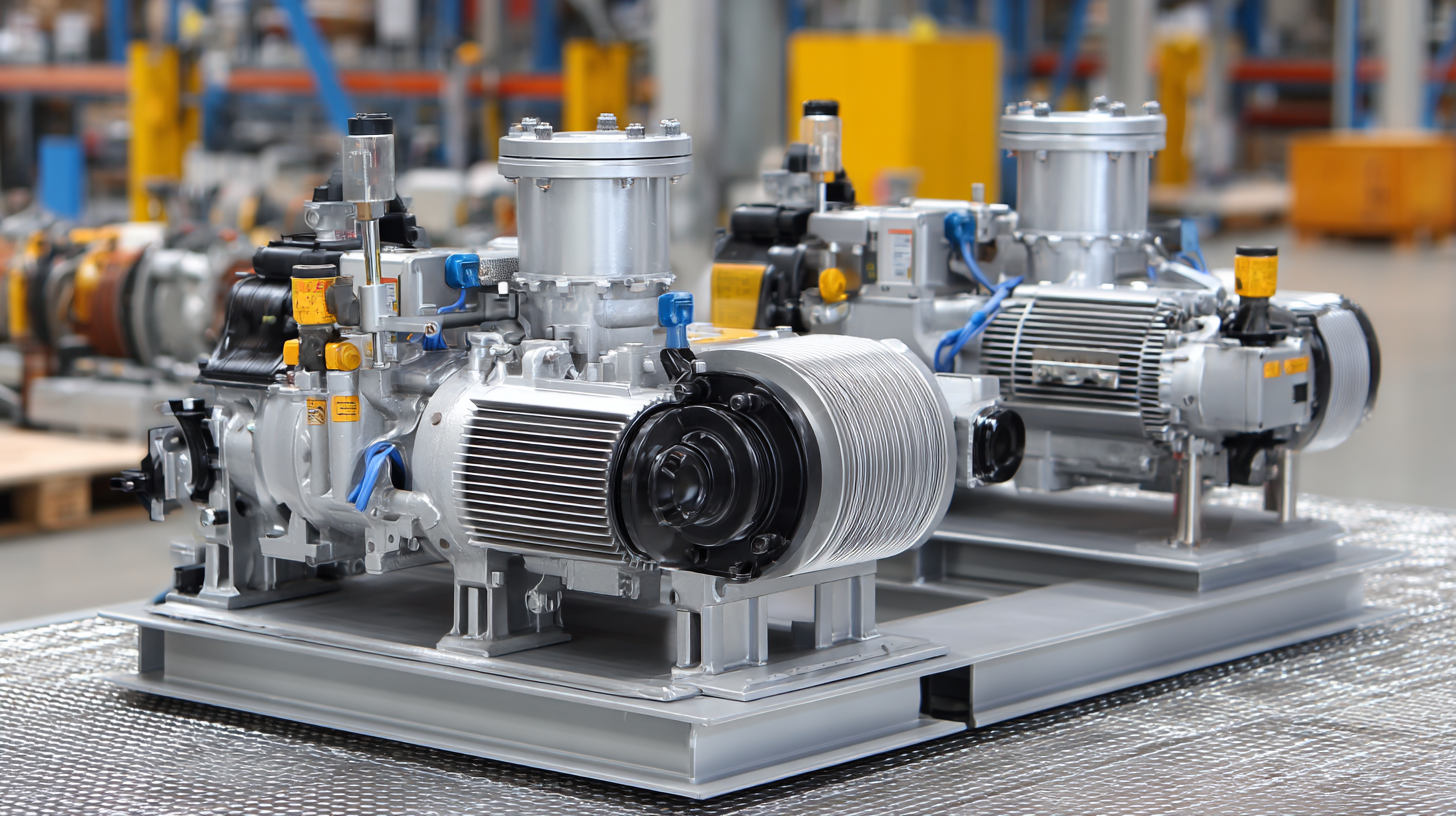

The Rise of Electric Hydraulic Pumps: Efficiency Gains and Industry Adoption Trends

The rise of electric hydraulic pumps is reshaping industrial applications by delivering unprecedented efficiency gains. As companies strive for sustainability and reduced operational costs, electric pumps are becoming the preferred choice over traditional hydraulic systems. These innovative pumps offer enhanced energy efficiency, lower noise levels, and reduced maintenance requirements, making them an ideal solution for various sectors including manufacturing and construction.

Tip: When considering the switch to electric hydraulic pumps, evaluate the specific power needs of your operations. This ensures you select a pump that aligns perfectly with your energy requirements while maximizing performance.

The trend towards electric hydraulic pumps is also influenced by advancements in technology. Smart controls and IoT integration are enabling operators to monitor performance in real-time, optimizing the hydraulic systems for better reliability and productivity. As industries continue to adopt these innovations, we can expect to see more sophisticated electric hydraulic systems capable of handling increasingly complex tasks.

Tip: Stay informed about the latest innovations in electric hydraulic technology. Engaging with industry newsletters and attending trade shows can provide insights into the best solutions available for your needs.

Innovative Materials in Hydraulic Components: Enhancing Durability and Performance

The landscape of hydraulic components is rapidly transforming, with innovative materials taking center stage in the quest for enhanced durability and performance. Traditional hydraulic systems have often been hampered by limitations associated with wear and tear, but the introduction of advanced materials is changing the game. High-performance polymers, composites, and specially engineered metals are now being utilized to create components that withstand extreme conditions, offering improved resistance to corrosion and fatigue. These materials not only extend the life span of hydraulic pumps and motors but also contribute to lighter, more efficient designs.

Furthermore, the application of these innovative materials is paving the way for new hydraulic technologies that deliver better functionality and efficiency. For instance, the use of composite materials can significantly reduce the weight of hydraulic components, leading to energy savings and enhanced system performance. Additionally, some new materials possess self-lubricating properties, which minimize friction and wear, further improving the reliability of hydraulic systems. As industries increasingly prioritize sustainability and efficiency, the ongoing evolution in materials technology is set to redefine not only the capabilities of hydraulic systems but also their role in industrial applications.

Smart Hydraulic Systems: Integrating IoT for Real-Time Monitoring and Maintenance

The integration of IoT in hydraulic systems is paving the way for transformative changes across industrial applications. By enabling real-time monitoring and maintenance, smart hydraulic systems significantly enhance operational efficiency and reliability. According to a recent report, the global hydraulic systems market is projected to grow by over 10% annually, driven by advancements such as predictive maintenance and automation technologies. These innovations not only minimize downtime but also reduce costs associated with equipment failures.

To maximize the benefits of smart hydraulic systems, consider implementing smart sensor technologies for valve and system performance monitoring. These sensors can provide critical data that helps in anticipating issues before they escalate, allowing for timely interventions. Additionally, adopting cloud-based platforms for data analysis can streamline information flow and improve decision-making processes within organizations.

As industries increasingly focus on sustainability, leveraging these advanced hydraulic technologies can lead to enhanced energy efficiency and reduced environmental impact. By staying ahead of the curve in adopting IoT-enabled hydraulic solutions, businesses can ensure they remain competitive in an evolving market.

The Role of Virtual Prototyping in Hydraulic Pump and Motor Development

The advancement of hydraulic pumps and motors is significantly influenced by the integration of virtual prototyping in their development processes. Virtual prototyping allows engineers and designers to create digital models of hydraulic systems, enabling them to simulate performance under various conditions without the need for physical prototypes. This approach not only accelerates the design phase but also helps to identify potential flaws early in the development cycle, ultimately resulting in more reliable and efficient products.

Moreover, virtual prototyping facilitates collaboration among cross-functional teams by providing a shared platform to visualize, test, and assess design specifications. Designers can experiment with different materials and configurations, using simulations to predict how changes will affect performance. This iterative process not only enhances innovation but also reduces the time and cost associated with traditional prototyping methods. As industries increasingly seek to improve efficiency and sustainability, the role of virtual prototyping in developing cutting-edge hydraulic pumps and motors becomes indispensable, driving forward the future of industrial applications.

The Future of Best Hydraulic Pumps and Motors Innovations Transforming Industrial Applications - The Role of Virtual Prototyping in Hydraulic Pump and Motor Development

| Innovation |

Description |

Key Benefits |

Expected Impact |

| Smart Hydraulic Pumps |

Hydraulic pumps integrated with IoT for real-time monitoring. |

Increased efficiency, reduced downtime, and predictive maintenance capabilities. |

Significantly enhances operational efficiency in industries. |

| Virtual Prototyping |

Using software simulations to design and test hydraulic systems. |

Reduces development time and costs while improving accuracy. |

Accelerates innovation cycle and product rollout. |

| Energy Efficient Motors |

Motors designed to consume less power without sacrificing performance. |

Lower operational costs and reduced environmental impact. |

Improves sustainability in industrial applications. |

| Modular Design |

Pumps and motors designed for easy customization and scalability. |

Enhanced adaptability to various applications and quick replacements. |

Increases flexibility in manufacturing and reduces lead times. |

| Advanced Materials |

Utilizing lightweight and durable materials to improve performance. |

Increased durability and reduced weight for ease of handling. |

Enhances overall reliability of hydraulic systems. |

Future Projections: Market Demand and Investment Opportunities in Hydraulic Technologies

As industries continue to evolve, the demand for advanced hydraulic technologies is surging. Future projections indicate a robust market growth driven by automation and the need for energy-efficient solutions. Investment opportunities abound, particularly in developing smart hydraulic systems that integrate IoT capabilities. Companies that embrace these innovations can expect to enhance their operational efficiency and reduce downtime, making them competitive in a marketplace that values agility and responsiveness.

When considering investment in hydraulic technologies, one key tip is to evaluate the scalability of new systems. Look for innovative hydraulic pumps and motors that can adapt as your business grows, ensuring that your investment remains relevant over time. Also, keep an eye on companies that prioritize sustainability in their design and manufacturing processes, as this will likely influence purchasing decisions in the near future.

Another important aspect to consider is the integration of predictive maintenance features. Choosing hydraulic systems equipped with sensors can minimize unexpected failures, allowing for timely interventions and cost savings. This proactive approach not only enhances productivity but also contributes to a sustainable operating environment, as well-maintained equipment tends to have a longer lifespan and requires fewer resources for repairs.