How to Enhance Your Machinery Efficiency with a Hydraulic Pump Using Industry Statistics

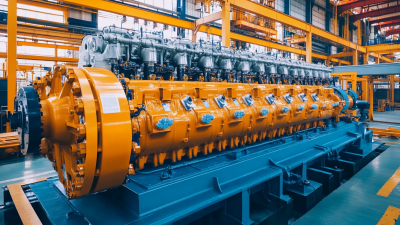

In an era where operational efficiency is paramount, industries are increasingly turning to advanced technologies to optimize their machinery performance. A hydraulic pump plays a critical role in enhancing the productivity of hydraulic systems, which, according to the American Fluid Power Association, is projected to reach a global market value of approximately $60 billion by 2025. This growth indicates a robust demand for hydraulic solutions across various sectors, including construction, manufacturing, and automotive. By leveraging accurate industry statistics and best practices, businesses can improve their hydraulic systems' efficiency, resulting in reduced downtime and increased output. Understanding the key factors influencing hydraulic pump performance is essential for companies looking to stay competitive and achieve significant cost savings.

Understanding the Role of Hydraulic Pumps in Machinery Efficiency Enhancement

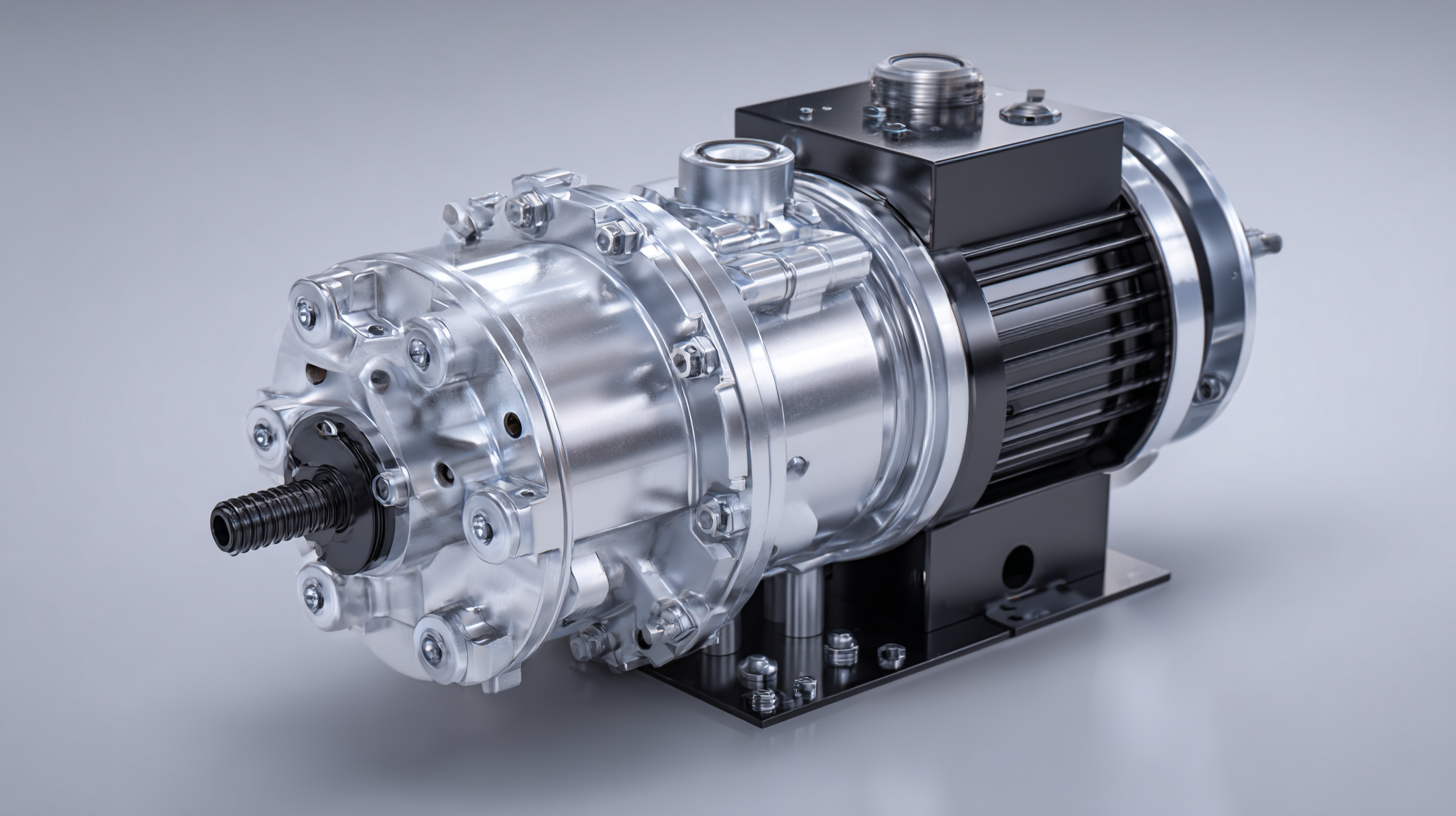

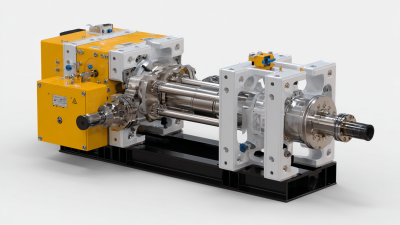

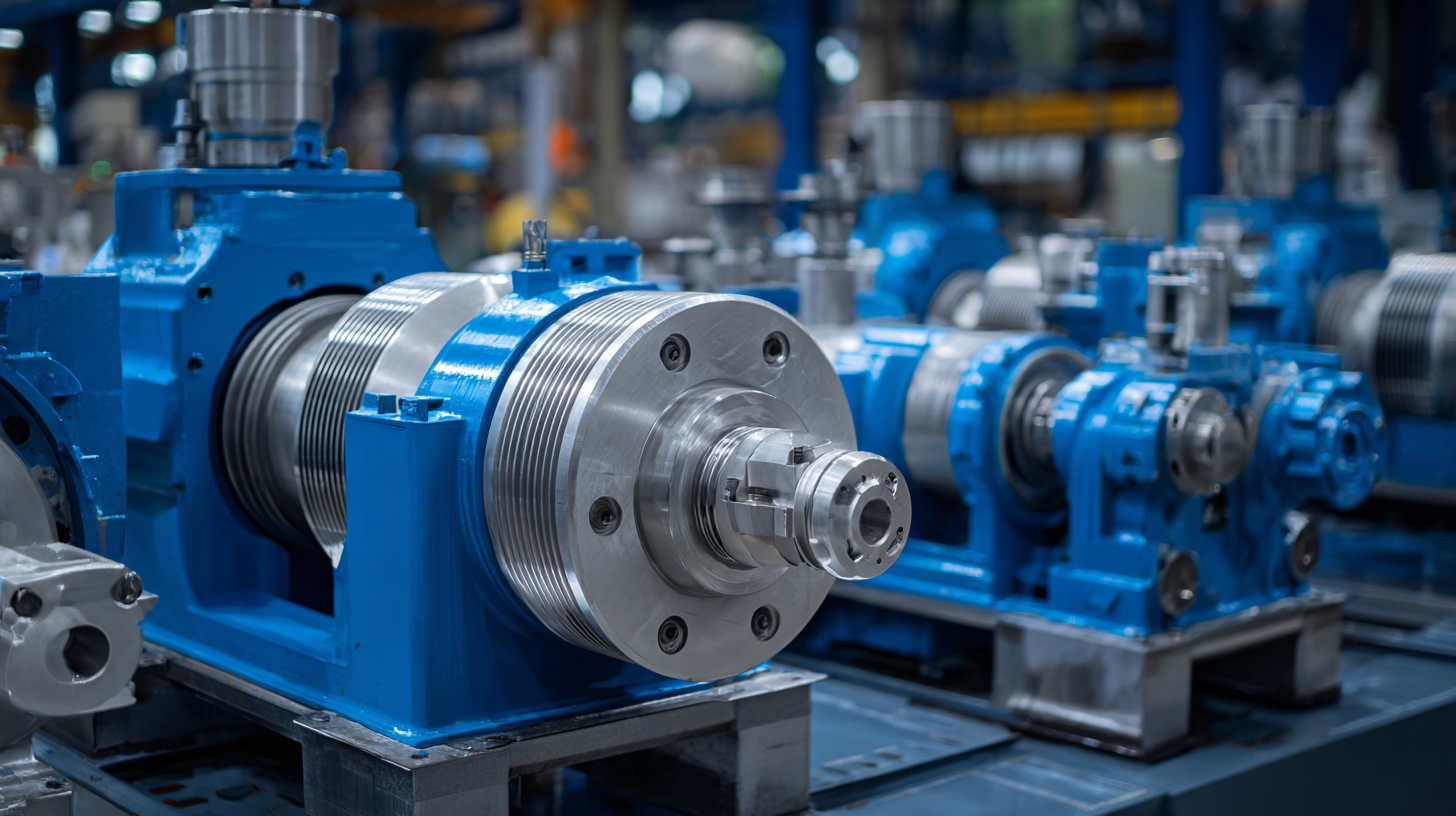

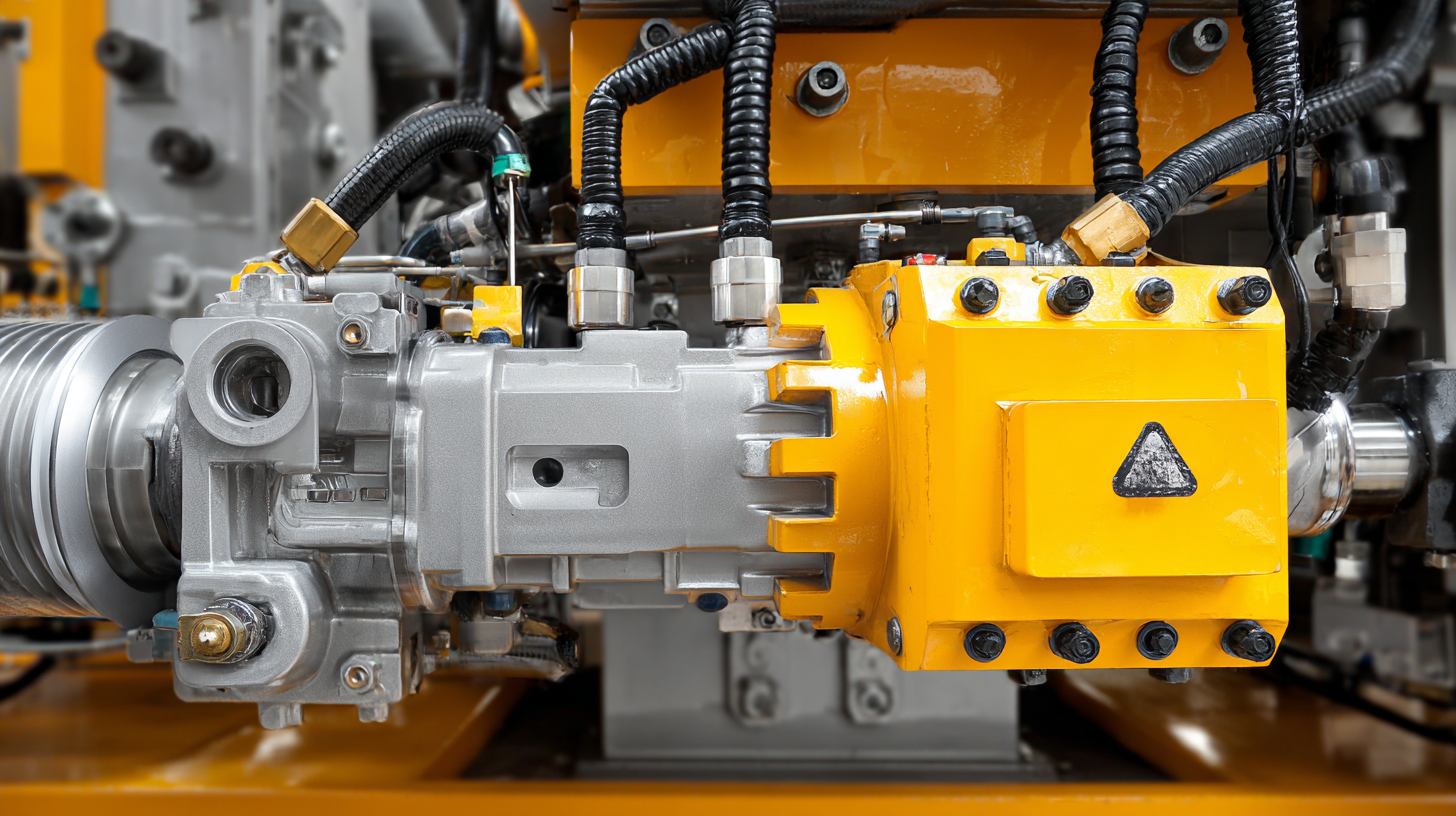

Hydraulic pumps play a crucial role in enhancing the efficiency of machinery across various industries. By converting mechanical energy into hydraulic energy, these pumps facilitate the transfer of power and movement within equipment, allowing for smoother operation and increased productivity. The ability to handle high-pressure fluids means that hydraulic pumps can perform tasks that would be challenging for other systems, such as lifting heavy loads or powering complex machinery with precision.

Incorporating hydraulic pumps into machinery not only improves overall efficiency but also helps in optimizing operational costs. Industry statistics indicate that businesses utilizing hydraulic systems can see significant reductions in energy consumption, leading to lower overhead expenses. Furthermore, the versatility of hydraulic systems enables them to be tailored for specific applications, ensuring that each piece of machinery functions at its best, thus prolonging equipment lifespan and reducing the need for frequent repairs. By understanding and implementing the role of hydraulic pumps effectively, organizations can drive substantial improvements in their machinery's performance.

Analyzing Industry Statistics on Hydraulic Pump Performance and Operational Costs

To enhance machinery efficiency with a hydraulic pump, it's crucial to analyze industry statistics that reveal performance metrics and operational costs. For instance, a recent report projected that the global aircraft hydraulic systems market will reach USD 12.2 billion by 2024, indicating a robust growth trajectory. This growth is driven by the increasing demand for efficient hydraulic systems in various sectors, including aviation and manufacturing. Understanding these trends allows businesses to optimize their hydraulic pump usage, ultimately lowering operational costs.

Tips: Regularly monitor your hydraulic system's performance against industry benchmarks. Implement preventive maintenance schedules to enhance pump lifespan and efficiency. Moreover, consider integrating IoT technologies, as they play a vital role in real-time data monitoring, which can lead to proactive decision-making and significant cost savings.

Additionally, a study on the circulating cooling water system found that operating costs are significantly impacted by ambient temperature changes. This highlights the importance of adapting machinery settings to environmental factors, ensuring that hydraulic systems are running efficiently under varying conditions. As the industry leans towards more innovative solutions, leveraging real-time analytics will be instrumental in achieving optimal operational performance.

How to Enhance Your Machinery Efficiency with a Hydraulic Pump Using Industry Statistics

| Pump Type |

Efficiency (%) |

Operational Cost ($/hour) |

Maintenance Cost ($/month) |

Lifespan (years) |

| Gear Pump |

85 |

25 |

200 |

10 |

| Vane Pump |

90 |

30 |

150 |

8 |

| Piston Pump |

92 |

40 |

250 |

15 |

| Screw Pump |

88 |

35 |

180 |

12 |

| Diaphragm Pump |

86 |

28 |

220 |

9 |

Identifying Key Factors That Influence Hydraulic Pump Efficiency in Machinery

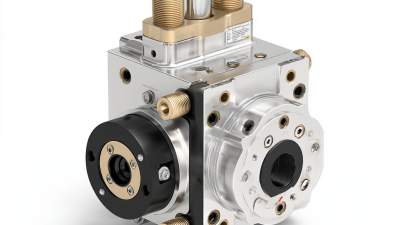

Hydraulic pumps play a crucial role in enhancing machinery efficiency, but several key factors can significantly influence their performance. One major factor is the design and type of the hydraulic pump itself. Different applications may require specific pump types—gear pumps, vane pumps, or piston pumps. Understanding the specific needs of your machinery can lead to better selections that optimize performance.

Another crucial aspect is the maintenance of the hydraulic system. Regular inspections and timely replacements of worn-out components help to prevent efficiency drops. It is essential to ensure that the hydraulic fluid remains clean and at the appropriate levels, as contamination can severely impact performance.

**Tips:**

1. Regularly check and replace filters to maintain fluid cleanliness and extend pump life.

2. Monitor operating temperatures; excessive heat can indicate problems with the pump or system and lead to efficiency losses.

3. Stay informed about advancements in hydraulic technology to ensure you are utilizing the most efficient pumps available for your application.

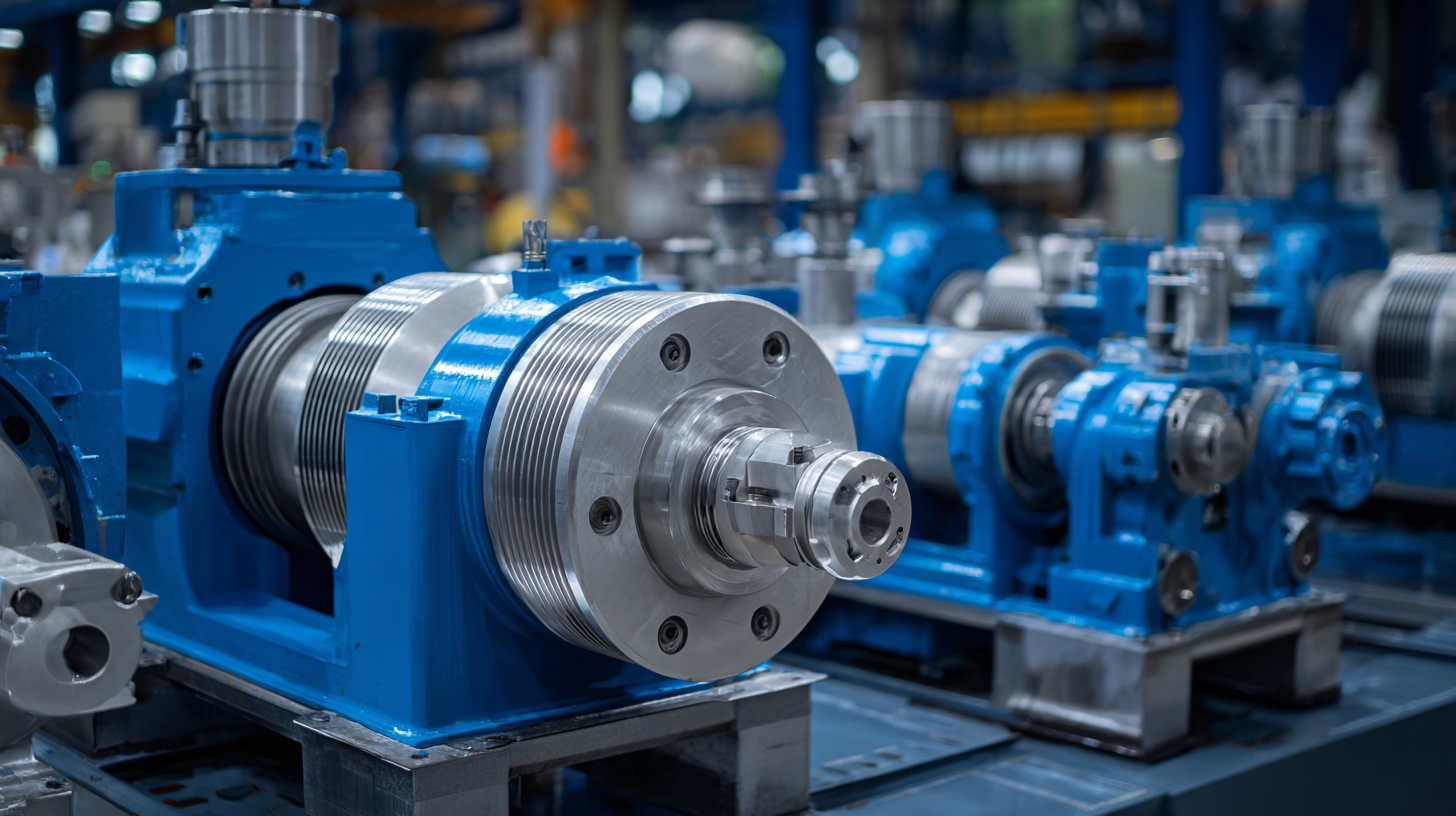

Comparative Study: Traditional vs. Modern Hydraulic Pump Technologies in Industry

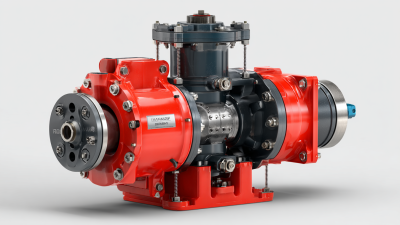

The efficiency of hydraulic pumps plays a crucial role in machinery performance across various industries. A comparative study of traditional versus modern hydraulic pump technologies reveals significant advancements in efficiency and operational cost. According to a report from the National Fluid Power Association, modern hydraulic systems can achieve up to 30% greater energy efficiency compared to their traditional counterparts due to innovations such as variable-speed drives and advanced control systems. These enhancements not only optimize energy consumption but also reduce greenhouse gas emissions, aligning industry practices with environmental regulations.

Furthermore, the adoption of modern hydraulic pump technologies has been shown to enhance reliability and reduce maintenance costs. A recent study published in the Journal of Hydraulic Engineering indicates that modern pumps experience 50% fewer failures than traditional models, primarily due to the implementation of smart diagnostics and predictive maintenance technologies. This shift allows for proactive maintenance strategies, minimizing downtime and extending the lifecycle of machinery. Industries leveraging these advancements are reporting an average 15% increase in overall productivity, demonstrating a clear competitive advantage in a rapidly evolving market.

Comparison of Efficiency Between Traditional and Modern Hydraulic Pump Technologies

Best Practices for Implementing Hydraulic Pumps to Maximize Machinery Output

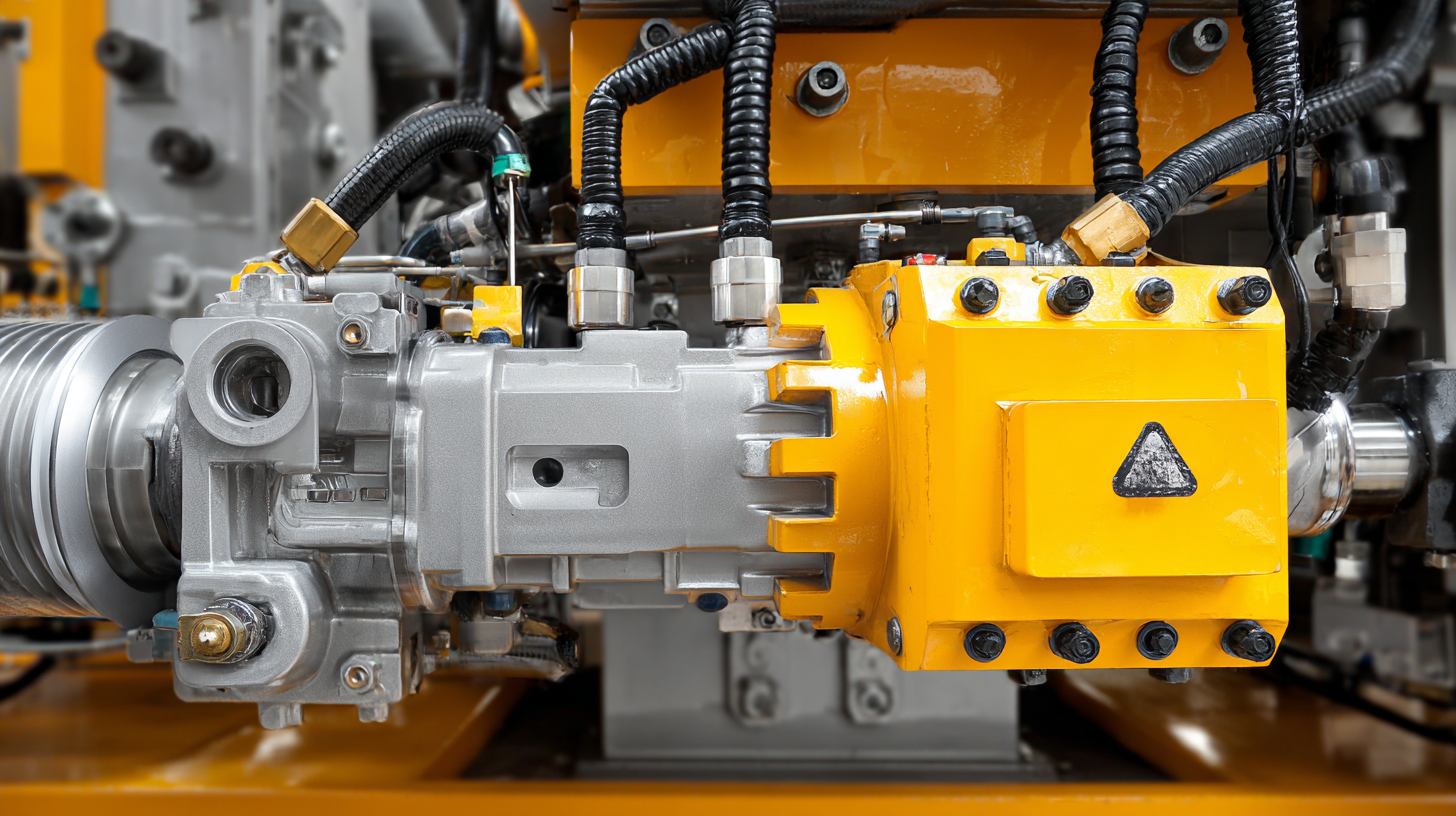

Implementing hydraulic pumps effectively can significantly boost machinery output. One of the best practices is to ensure that the hydraulic system is properly sized for the specific application. This involves selecting a pump that matches the flow and pressure requirements of the machinery. Over-sizing or under-sizing the pump can lead to inefficiencies, increasing energy consumption and reducing overall performance. Regular maintenance and timely inspections also play a crucial role in maintaining optimal pump function, preventing wear and tear, and avoiding unexpected downtimes.

Another important aspect is the integration of advanced hydraulic technologies, such as variable displacement pumps and electronic control systems. These innovations allow for more precise control of the hydraulic flow and pressure, resulting in improved responsiveness and energy efficiency. Additionally, training operators to understand the hydraulic systems' operational nuances can lead to better handling and adjustment of machinery, maximizing productivity while minimizing risk of malfunctions. By adhering to these best practices, industries can harness the full potential of hydraulic pumps, leading to enhanced machinery efficiency and productivity.