How to Choose the Best Main Hydraulic Pump for Your Industrial Needs

In the evolving landscape of industrial machinery, the selection of the right Main Hydraulic Pump is critical for optimizing performance and efficiency. According to a recent report by the International Hydraulic Association, the hydraulic pump market is expected to grow at a CAGR of 5.4% from 2023 to 2028, reflecting the increasing reliance on hydraulic systems across various sectors, including manufacturing, construction, and agriculture. In 2025, technological advancements such as smart hydraulics and digital control systems are anticipated to revolutionize how these pumps function, enhancing both precision and reliability. Additionally, as industries seek to reduce their carbon footprints, alternative hydraulic technologies, including electric and hybrid systems, are gaining traction. Therefore, understanding the different types of Main Hydraulic Pumps and their applications is essential for industry stakeholders aiming to make informed purchasing decisions that align with future trends and performance standards.

Understanding the Importance of a Hydraulic Pump in Industrial Applications

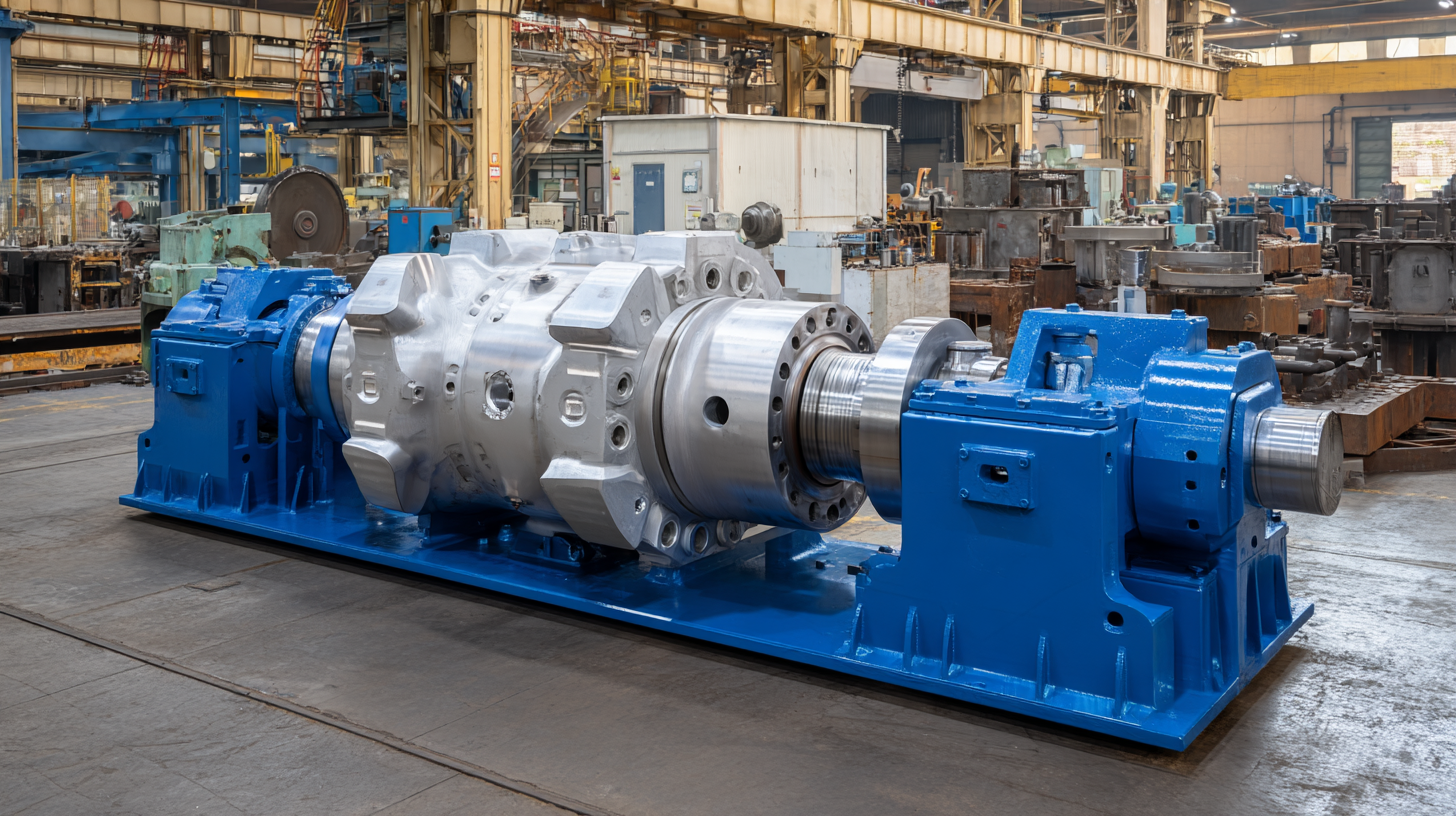

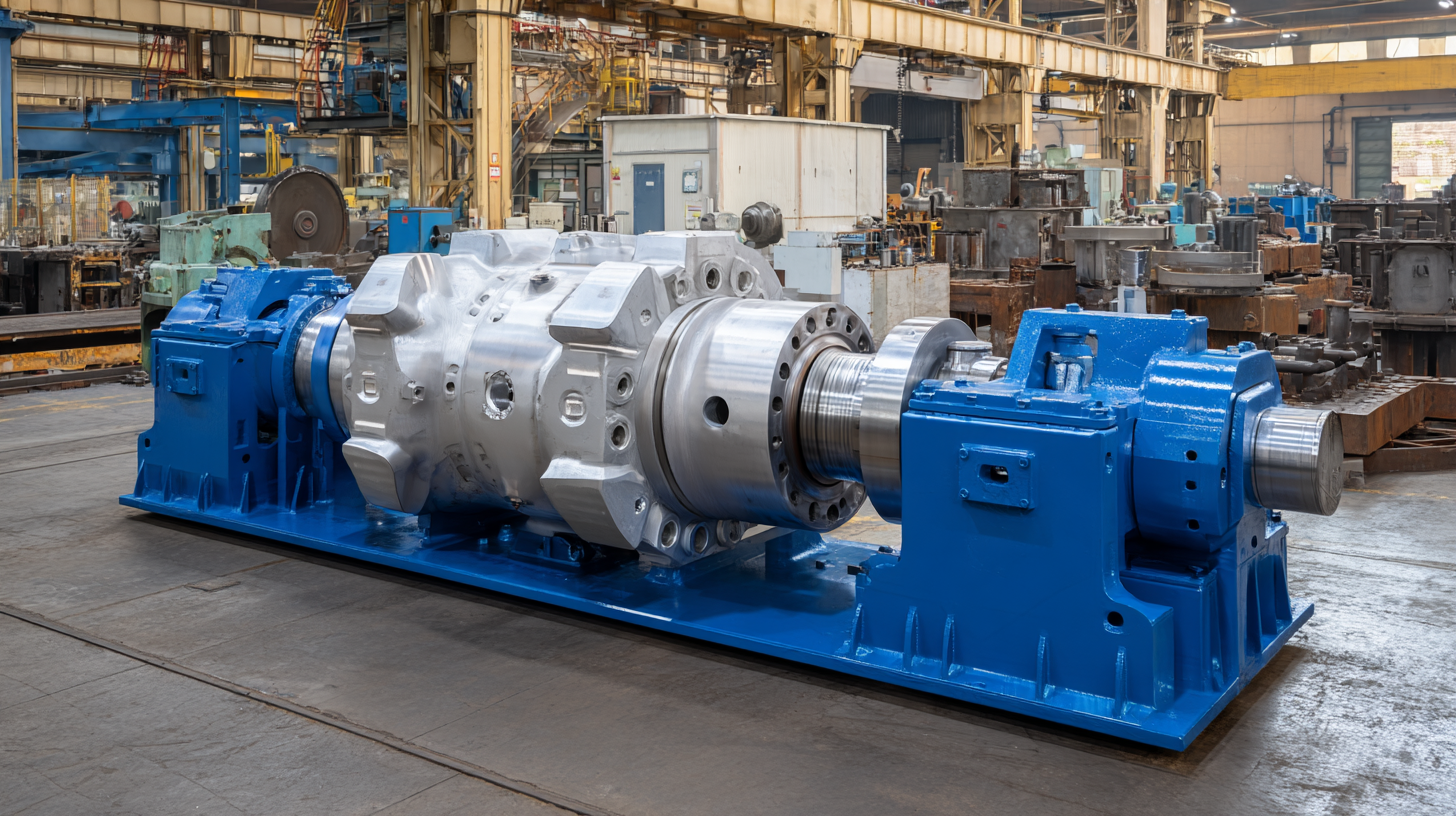

A hydraulic pump plays a critical role in industrial applications, delivering the fluid power necessary for various machinery and systems to function effectively. These pumps convert mechanical energy into hydraulic energy, enabling equipment such as forklifts, excavators, and conveyor systems to operate with precision and reliability. Understanding the importance of a hydraulic pump involves recognizing how its performance directly influences productivity and operational efficiency in a facility.

The choice of an appropriate hydraulic pump is vital for ensuring that machinery meets the specific demands of the tasks at hand. Factors such as flow rate, pressure, and response time must be considered, as they affect not only how well the equipment performs but also how long it lasts. An ideal hydraulic pump should provide consistent performance under various conditions, minimizing downtime and maintenance costs. Therefore, a meticulous assessment of your industrial needs will guide you in selecting the best pump, ultimately enhancing your operation's capability and sustainability.

How to Choose the Best Main Hydraulic Pump for Your Industrial Needs

| Pump Type |

Flow Rate (L/min) |

Pressure Rating (Bar) |

Power Requirement (kW) |

Best Application |

| Gear Pump |

20-400 |

10-200 |

5-75 |

General Machinery |

| Piston Pump |

10-600 |

50-700 |

10-150 |

High-Pressure Systems |

| Vane Pump |

15-300 |

20-400 |

3-60 |

Mobile Equipment |

| Gerotor Pump |

5-100 |

15-250 |

2-20 |

Agricultural Equipment |

Key Factors to Consider When Selecting a Main Hydraulic Pump

Choosing the right main hydraulic pump for industrial applications requires careful consideration of several key factors to ensure optimal performance. One critical aspect is the selection of hydraulic fluids. The right hydraulic fluid plays a significant role in system efficiency, with reports indicating that improper fluid choice can lead to a 10-15% decrease in performance. Moreover, hydrolytic stability is essential; fluids with suitable properties can safeguard against water contamination, which is known to degrade system functionality.

Choosing the right main hydraulic pump for industrial applications requires careful consideration of several key factors to ensure optimal performance. One critical aspect is the selection of hydraulic fluids. The right hydraulic fluid plays a significant role in system efficiency, with reports indicating that improper fluid choice can lead to a 10-15% decrease in performance. Moreover, hydrolytic stability is essential; fluids with suitable properties can safeguard against water contamination, which is known to degrade system functionality.

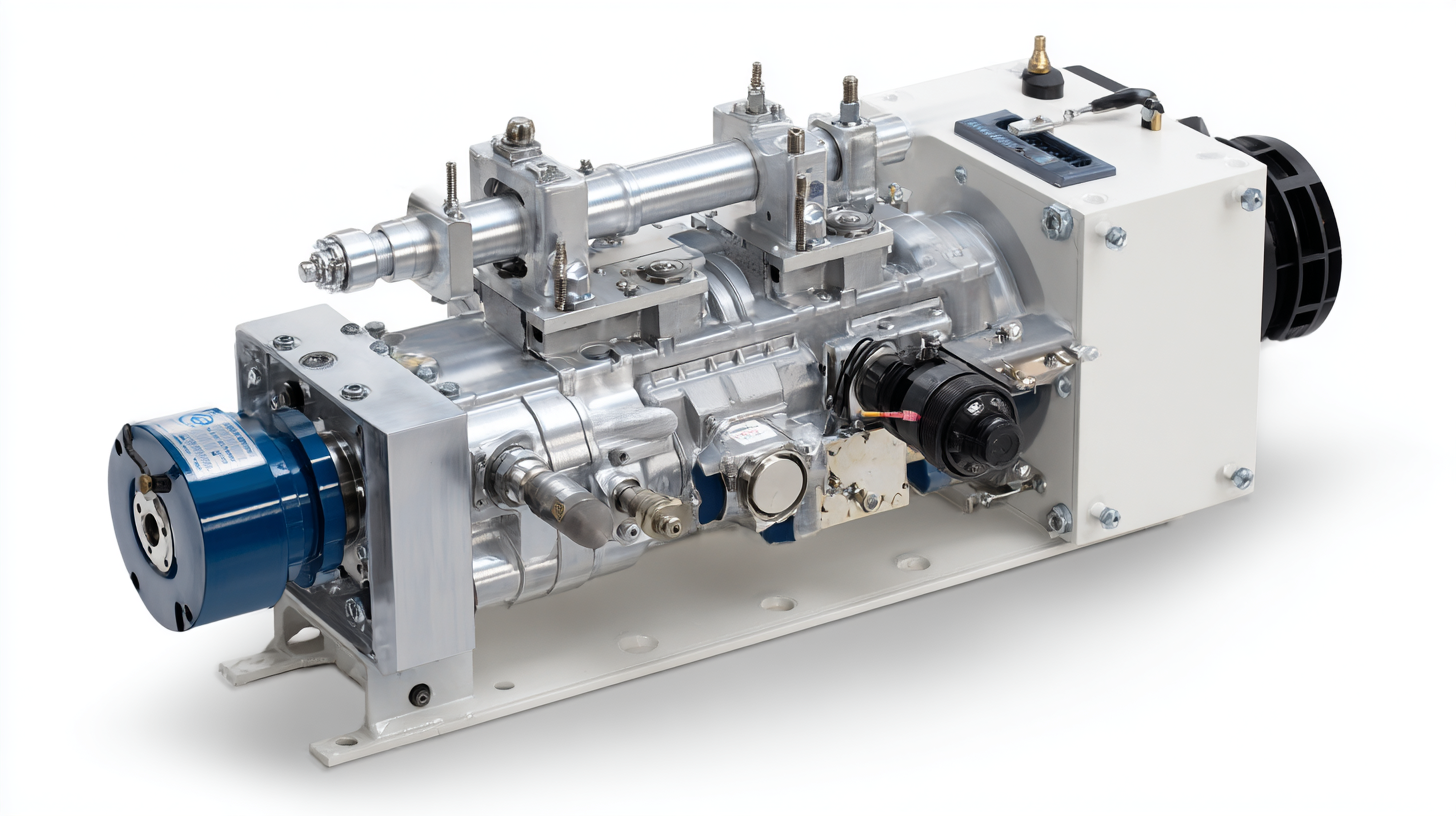

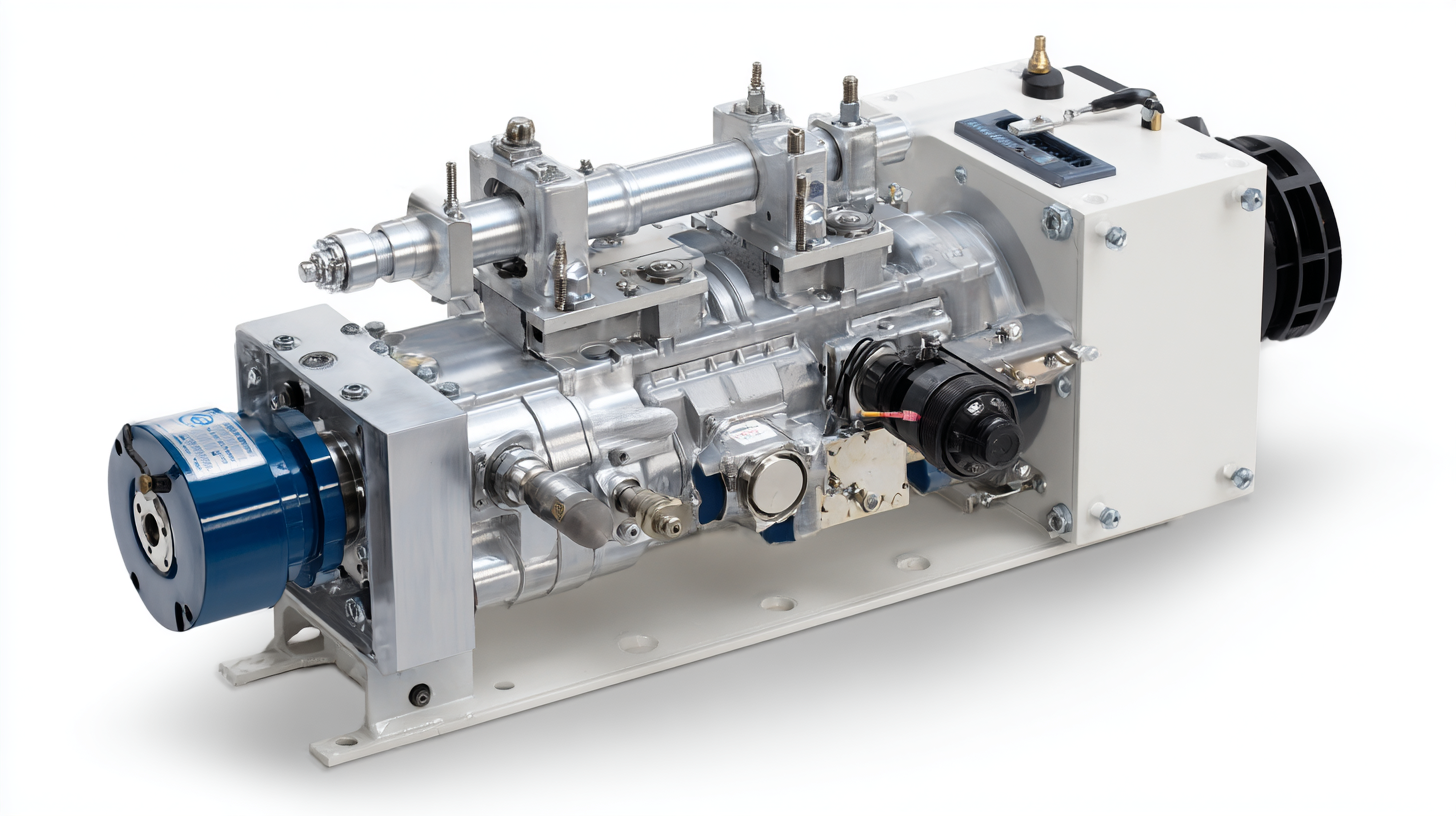

When selecting a hydraulic pump, it’s vital to take into account the energy efficiency of the system. The emergence of electro-hydraulic systems has gained traction, as these systems enable better energy utilization and recovery, aligning with modern sustainability goals. A recent study highlighted that electro-hydraulic hybrid vehicles can enhance energy efficiency significantly compared to traditional hydraulic systems.

Tips: Always assess the required hydraulic fluid characteristics tailored to your specific application needs. When integrating new systems, consider adopting a phased approach for upgrades to minimize downtime and costs. Finally, opt for pumps that utilize advanced designs, as these not only improve efficiency but also contribute to reduced noise levels in operations.

Different Types of Hydraulic Pumps and Their Applications

When selecting a hydraulic pump for industrial applications, it's crucial to understand the different types of hydraulic pumps and their specific uses. The market is rapidly evolving, with a significant growth projection for hydraulic pumps due to increased demand for efficient hydraulic systems. Gear pumps, which dominate the market, are widely used in various applications ranging from construction equipment to automotive industries. Their ability to provide high flow rates at relatively low pressure makes them ideal for many industrial tasks.

Mobile hydraulic systems are continually advancing, incorporating new technologies to enhance efficiency and reduce environmental impact. Innovations such as sensor technologies for monitoring hydraulic valve performance are helping to overcome traditional challenges, ensuring better reliability and enhanced operational capabilities. Furthermore, there is a growing trend toward integrating green hydraulic power solutions that promise improved energy efficiency, addressing both performance needs and sustainability concerns. Understanding these advancements is vital for making informed decisions when choosing a hydraulic pump that aligns with your industrial needs.

Evaluating Pump Performance Metrics for Optimal Efficiency

When selecting a main hydraulic pump for industrial applications, evaluating pump performance metrics is crucial to achieving optimal efficiency. According to recent energy efficiency reports, technical advancements play a significant role in enhancing the competitiveness of products in global markets. Specifically, improvements in hydraulic pump designs can lead to significant gains in energy efficiency—an essential consideration given the increasing energy costs and environmental regulations impacting various industries.

Performance metrics such as flow rate, pressure, and energy consumption must be meticulously assessed. For instance, a study reveals that hydraulic pumps with improved volumetric efficiency can reduce overall energy consumption by up to 20%. Additionally, the integration of advanced monitoring tools allows operators to collect real-time data, ensuring that pump performance is continuously optimized. This aligns with the trend of using machine learning and predictive models, which have been shown to enhance the operational efficiency of equipment across sectors, from shipping to manufacturing.

Implementing these performance metrics effectively not only helps in achieving desired operational outcomes but also contributes to sustainability goals. In a world where energy-efficient technologies are increasingly critical, choosing the right hydraulic pump backed by rigorous performance evaluation can set businesses on a path toward both economic and environmental benefits.

Hydraulic Pump Performance Metrics

Common Mistakes to Avoid When Choosing Hydraulic Pumps for Industry

When selecting a hydraulic pump for industrial applications, avoiding

common pitfalls can save both time and resources.

One major mistake many make is underestimating the required flow rate and pressure.

It’s crucial to accurately assess the operational demands of your machinery to ensure that the pump can handle the workload efficiently.

Failure to do so may lead to pump underperformance or premature failure, ultimately affecting production processes.

Another frequent error involves overlooking

compatibility with existing systems.

Each hydraulic system has unique specifications, and choosing a pump that does not align with your equipment

can cause inefficiencies and malfunctions. Pay close attention to factors such as connection sizes, mounting options,

and fluid compatibility. Conducting thorough research or consulting with experts can help mitigate these issues

and ensure you select a pump that integrates seamlessly into your operations.

Furthermore, neglecting maintenance requirements is a common misstep.

It’s essential to consider not only the initial purchase but also the ongoing maintenance needs of the hydraulic pump.

Some pumps may seem attractive due to low initial costs but can lead to higher long-term expenses due to frequent repairs or replacements.

Prioritizing durability and ease of maintenance will lead to more sustainable operations in the long run.