China's Leading Hydraulic Pump Motors Redefining Global Manufacturing Excellence

In recent years, China's hydraulic pump motors have emerged as a formidable force in reshaping global manufacturing standards, driven by innovation, efficiency, and advanced technology. According to a report by MarketsandMarkets, the hydraulic pump market is projected to reach USD 38.1 billion by 2025, growing at a CAGR of 5.3% from 2020. This growth underscores the increasing reliance on hydraulic systems across various industries, including construction, agriculture, and aerospace, where precision and performance are paramount. China's commitment to enhancing the quality and capabilities of hydraulic pump motors stands out, as manufacturers leverage digital technologies and big data analytics to optimize production processes.

This blog will explore the key factors contributing to the excellence of hydraulic pump motors in China and their impact on setting new benchmarks for global manufacturing efficiency.

Innovative Technologies Driving China's Hydraulic Pump Motors Industry Forward

China’s hydraulic pump motors industry is undergoing a remarkable transformation, driven by innovative technologies that redefine manufacturing standards. At the forefront of this evolution are advancements in smart automation, allowing for increased precision and efficiency in production processes. With the integration of IoT and AI, manufacturers can now monitor performance in real-time, leading to enhanced reliability and reduced downtime. This technological shift not only boosts productivity but also significantly lowers operational costs, setting a new benchmark in the industry.

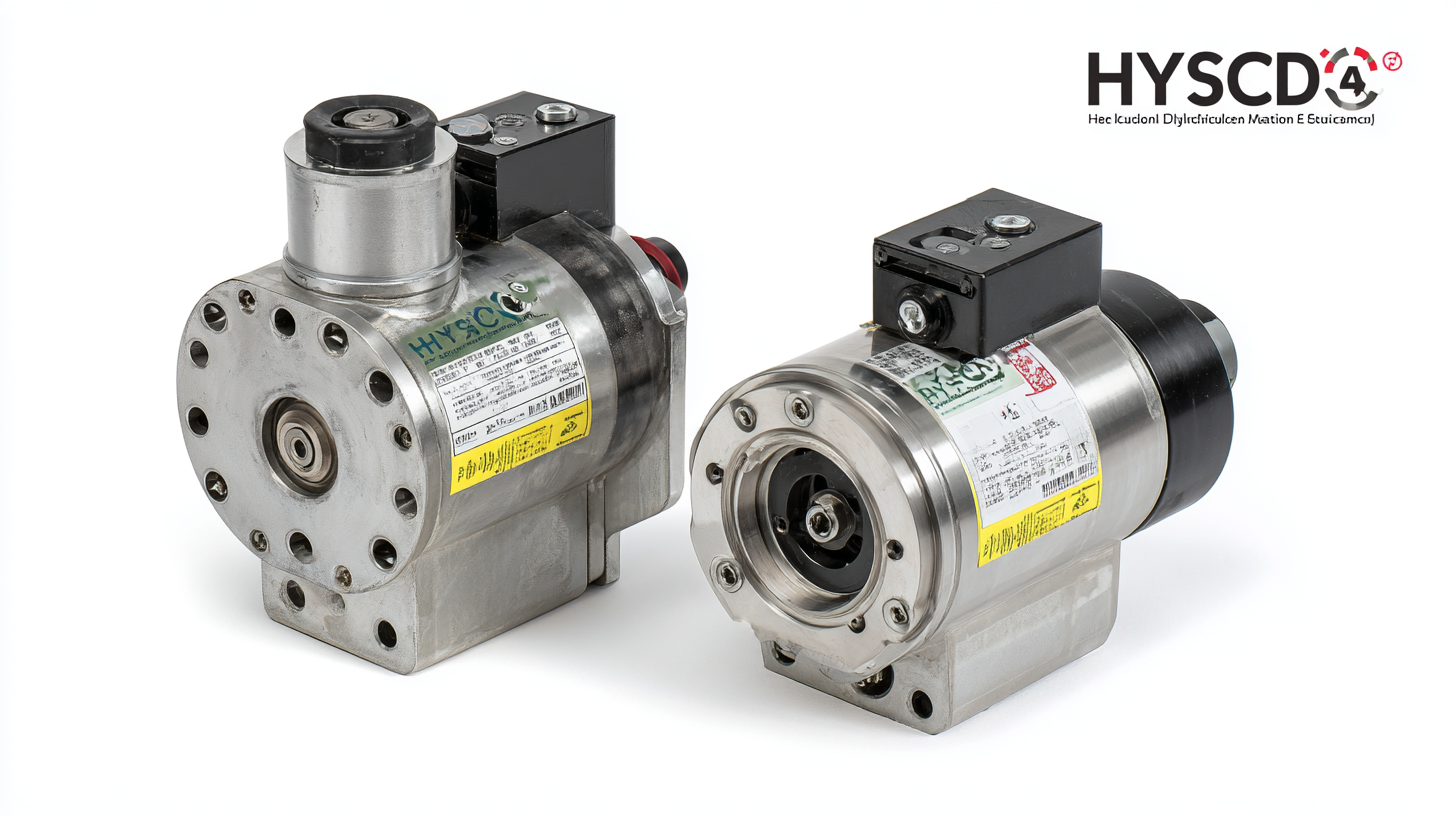

Furthermore, advancements in materials science are enhancing the durability and performance of hydraulic pump motors. The use of lightweight, high-strength materials is paving the way for more compact designs without compromising power output. This ongoing innovation is crucial as global markets demand more energy-efficient and environmentally friendly solutions.

China's commitment to research and development in hydraulic systems is driving the entire industry forward, positioning it as a key player in the global manufacturing landscape and exemplifying excellence in engineering and design.

Sustainability Practices in China’s Hydraulic Pump Manufacturing

In recent years, China's hydraulic pump manufacturing sector has increasingly embraced sustainability practices, setting new benchmarks for environmental responsibility in global manufacturing. By integrating green technologies and renewable energy sources, manufacturers are not only enhancing their production efficiency but also significantly reducing their carbon footprint. This shift is evident in the implementation of advanced recycling processes, where companies prioritize the reuse of materials, thus minimizing waste and conserving valuable resources.

Moreover, the focus on sustainability extends to the entire supply chain, encouraging collaboration with suppliers who share similar environmental values. Through rigorous assessments and certifications, manufacturers are fostering a culture of sustainability that permeates every aspect of their operations. This proactive approach not only meets the growing consumer demand for eco-friendly products but also positions Chinese hydraulic pump manufacturers as leaders in the global market, showcasing their commitment to innovation and environmental stewardship.

As these practices are refined and expanded, they pave the way for a more sustainable future in manufacturing, influencing industry standards worldwide.

Competitive Pricing and Cost-Effectiveness in Global Markets

China’s hydraulic pump motors are increasingly dominating the global manufacturing landscape, particularly due to their competitive pricing and cost-effectiveness. Recent industry reports indicate that China accounted for over 30% of the global hydraulic pump market in 2022, showcasing the nation’s impressive production capabilities and innovation in engineering. This growth trajectory is largely attributed to advancements in manufacturing technologies and economies of scale, allowing Chinese manufacturers to offer high-quality products at lower prices compared to their counterparts in North America and Europe.

Furthermore, the cost advantage is not merely a reflection of lower labor costs; it also stems from significant investments in automation and supply chain optimization. According to a report by MarketsandMarkets, the hydraulic equipment market is expected to reach USD 50 billion by 2025, with Chinese manufacturers predicted to maintain a strong competitive edge. As companies worldwide seek to enhance efficiency while managing production costs, Chinese hydraulic pump motors, with their robust performance and budget-friendly pricing, are poised to redefine standards in manufacturing excellence across various sectors.

Quality Control Measures Ensuring Excellence in Hydraulic Pump Motors

In the competitive landscape of global manufacturing,

China's hydraulic pump motors have emerged as a beacon of excellence,

largely due to rigorous quality control measures. The production of hydraulic pump motors demands

precision and reliability, and this is where Chinese manufacturers excel.

By implementing comprehensive quality management systems, they ensure that each motor meets stringent

international standards. From initial design to final testing, every stage of production is meticulously monitored,

allowing manufacturers to pinpoint potential issues before they escalate.

Moreover, the integration of advanced technologies into the quality control process

has revolutionized the manufacturing of hydraulic pump motors. Automated inspection systems, coupled with data analytics,

enable real-time adjustments and enhance production consistency. These innovations not only streamline operations but also

significantly reduce defects, leading to superior product reliability. As a result, China's hydraulic pump motors are not just

meeting the demands of the market but are also setting new benchmarks for excellence, reinforcing the country's position as

a leader in global manufacturing.

Future Trends in Hydraulic Pump Technology and Manufacturing Strategies

The hydraulic pump technology landscape is continuously evolving, driven by advancements in manufacturing strategies and a focus on sustainability. As industries seek to enhance efficiency and reduce their environmental impact, innovations such as variable displacement pumps and advanced materials are becoming essential. These technologies not only improve performance but also extend the lifespan of hydraulic systems, making them more cost-effective for businesses.

Tip: When selecting hydraulic pump motors, consider the compatibility with existing systems and the potential for future upgrades. Investing in flexible solutions that can adapt to upcoming trends will ensure sustainable growth.

Moreover, the integration of smart technology into hydraulic pumps is a game-changer. IoT-enabled systems provide real-time monitoring and diagnostics, allowing for predictive maintenance that minimizes downtime. This technological shift aligns with the global push for more intelligent manufacturing strategies, ensuring that businesses remain competitive in the market.

Tip: Always evaluate the long-term benefits of integrating smart technology into your hydraulic systems. While the initial investment may be higher, the potential savings from reduced maintenance and enhanced operational efficiency can yield substantial returns.