Maximize Efficiency with 12 Key Features of Bi Directional Hydraulic Pumps for Global Procurement

In the ever-evolving landscape of global procurement, efficiency is paramount. One innovative solution that has emerged to meet this demand is the Bi Directional Hydraulic Pump. This advanced technology not only enhances operational productivity but also optimizes resource utilization in various industrial applications. As businesses strive to streamline their processes and reduce costs, understanding the key features of these pumps becomes essential for sourcing and procurement teams looking to harness their full potential.

This blog delves into the twelve crucial features of Bi Directional Hydraulic Pumps, illustrating how they can significantly improve the procurement process. From increased versatility and reliability to improved energy efficiency, these pumps are designed to tackle the complexities of modern machinery and systems. By maximizing the benefits derived from these innovative pumps, organizations can position themselves at the forefront of their industries, ensuring sustained growth and competitiveness in a global marketplace. Join us as we explore the unparalleled advantages that Bi Directional Hydraulic Pumps bring to the procurement table.

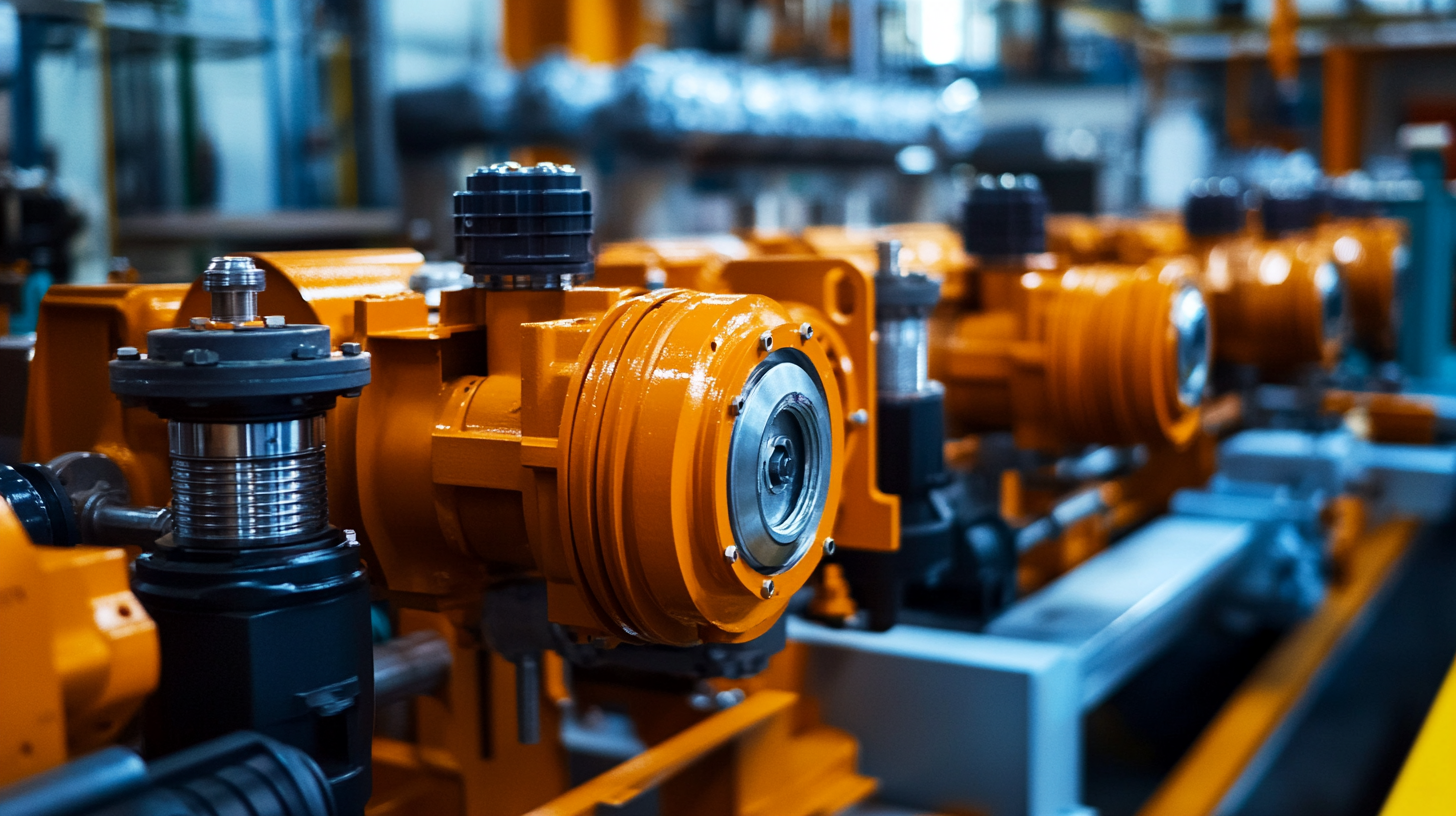

Understanding the Basics of Bi-Directional Hydraulic Pumps in Procurement

Bi-directional hydraulic pumps play a crucial role in modern procurement processes, particularly in industries where fluid movement and control are essential. Understanding the basics of these pumps can help procurement professionals make informed decisions that enhance operational efficiency. Bi-directional hydraulic pumps are designed to facilitate the movement of hydraulic fluid in two directions, allowing for greater versatility in applications such as construction machinery, automotive systems, and industrial equipment.

One of the key advantages of bi-directional hydraulic pumps is their ability to provide consistent flow regardless of the direction of movement. This characteristic not only improves the responsiveness of hydraulic systems but also ensures smoother operation and reduced energy consumption. Furthermore, recognizing the basic engine parameters, such as pressure ratings and flow rates, is essential for procurement teams to select pumps that meet the specific needs of their operations.

Incorporating bi-directional hydraulic pumps into procurement strategies can lead to significant improvements in performance and cost savings. As industries continue to evolve, understanding the dynamics of these pumps will not only enhance immediate procurement outcomes but also contribute to long-term operational success. By focusing on the fundamental features and applications of bi-directional hydraulic pumps, procurement professionals can maximize efficiency and align with the demands of the global market.

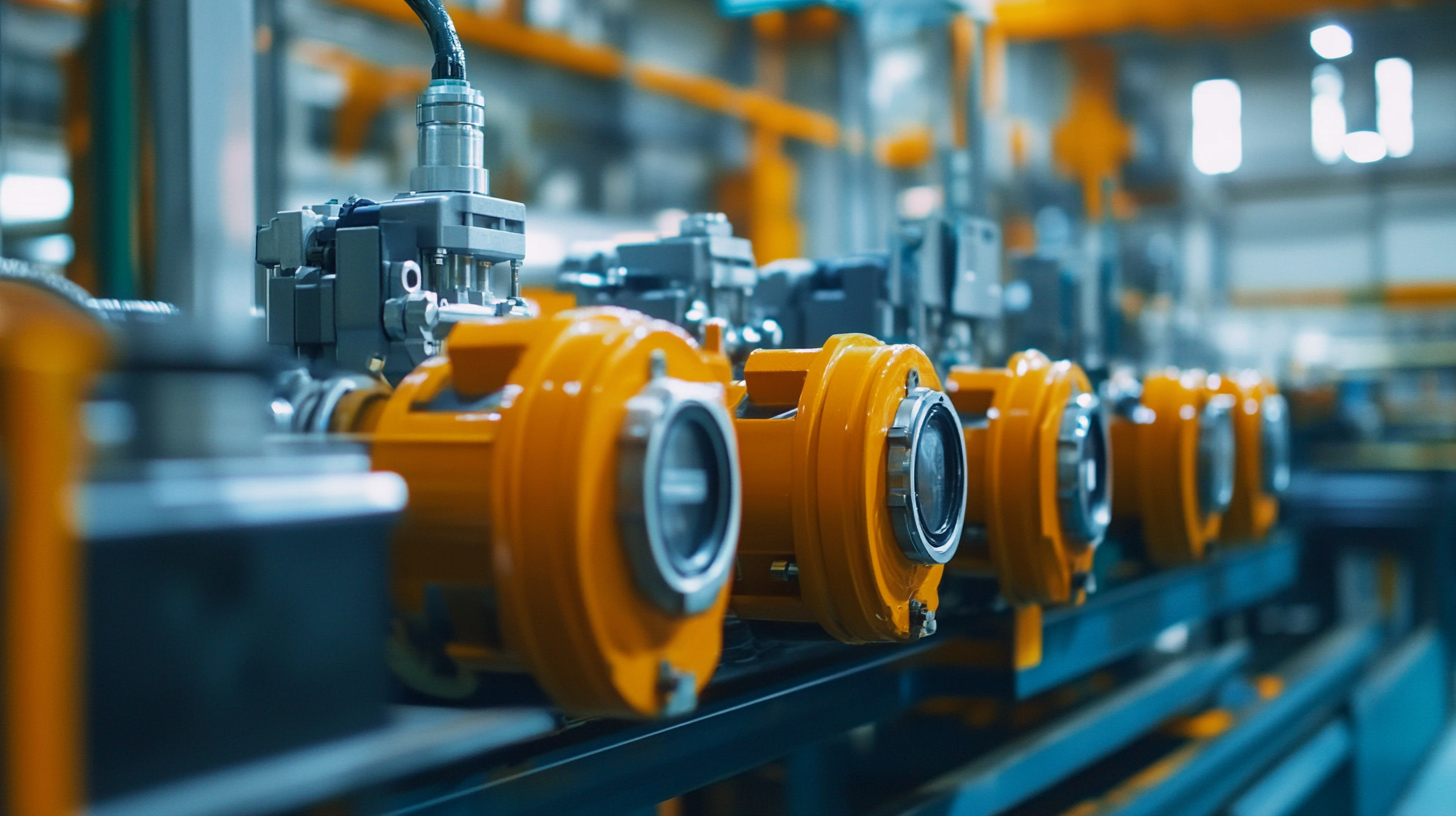

Key Advantages of Bi-Directional Hydraulic Pumps for Global Operations

Bi-directional hydraulic pumps are rapidly becoming essential in global operations, offering unique advantages that enhance efficiency and productivity. These pumps excel in applications requiring fluid movement in both directions, making them ideal for use in sophisticated machinery including hybrid propulsion systems. For instance, their integration in innovative solutions demonstrates how advanced hydraulic systems can streamline operation and reduce energy consumption, which is vital for modern procurement strategies.

Recent advancements in the field, such as the emerging electro-hydraulics and IIoT applications, further emphasize the benefits of bi-directional hydraulic pumps. Electro-hydraulics improve control and functionality of off-highway vehicles, indicating a shift towards systems that prioritize precision and responsiveness. Additionally, the use of such hydraulic technology in agricultural equipment, like tandem hydraulic pumps in manure spreaders, showcases practical implementations that boost operational efficiency and minimize waste, which aligns with global sustainability goals.

The mining sector also benefits significantly from bi-directional hydraulic systems, where robust performance is crucial. With machines outfitted with advanced load-sensing hydraulics, operators can manage heavy loads and challenging conditions more effectively. This effectively highlights the versatility of bi-directional pumps, demonstrating their adaptability across various global industries and solidifying their importance in modern procurement and operational strategies.

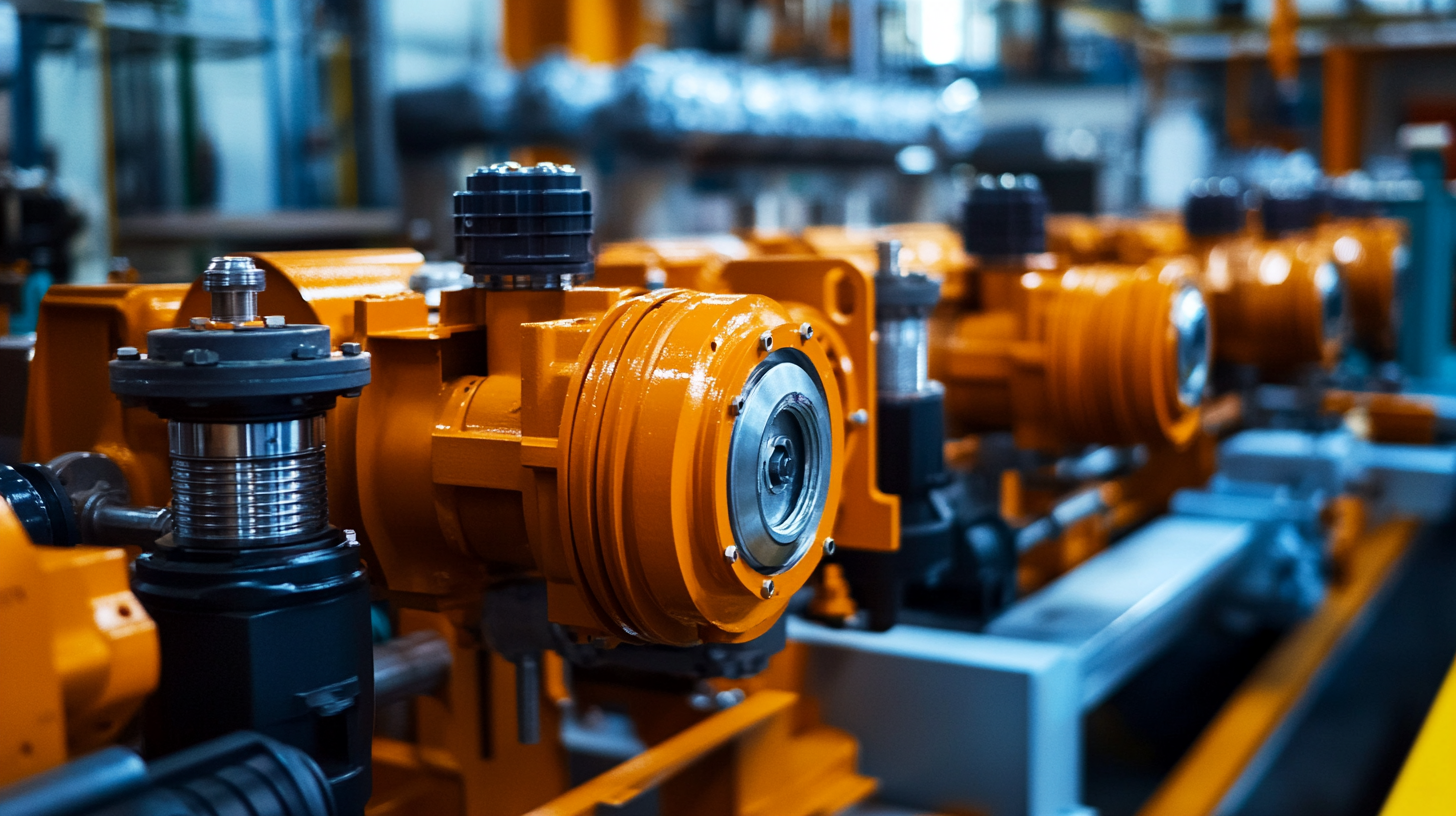

Critical Features to Look for in Bi-Directional Hydraulic Pumps

When considering the critical features of bi-directional hydraulic pumps for global procurement, it's essential to focus on efficiency and performance. Bi-directional hydraulic pumps are designed to facilitate fluid flow in both directions, enhancing operational flexibility and efficiency in various machine applications. One of the foremost attributes to evaluate is the pump's efficiency rating. An efficient pump minimizes energy consumption while maximizing performance, thereby reducing operational costs over time.

Another critical aspect is the robustness and reliability of the pump materials. Durable materials not only extend the lifespan of the pump but also ensure consistent performance even under extreme conditions. Additionally, monitoring technologies integrated into the pump can provide real-time data on operational status, allowing for proactive maintenance and reducing downtime.

Compatibility with existing systems is also vital. A bi-directional hydraulic pump should be adaptable to various hydraulic circuits without extensive modifications, making it an ideal choice for both new installations and retrofitting projects. Lastly, ease of installation and maintenance must not be overlooked; user-friendly designs can significantly reduce labor costs and enhance overall system reliability. Understanding these features can lead to more informed decisions in the procurement of hydraulic systems, effectively maximizing efficiency.

How Bi-Directional Hydraulic Pumps Enhance Operational Efficiency

In today's fast-paced industrial landscape, the quest for operational efficiency continues to drive innovation, and bi-directional hydraulic pumps are at the forefront of this movement. These pumps are engineered to enhance performance through their ability to facilitate fluid flow in two directions, which is particularly beneficial in complex systems where both lifting and lowering actions are required. Their unique design allows for more effective energy use, reducing the overall consumption of resources while still delivering consistent power output.

Recent analyses have highlighted how bi-directional hydraulic technology contributes to energy savings, especially in processes reliant on hydraulic systems. For instance, the application of inlet guide vanes can optimize the flow characteristics of hydraulic machinery under various operational conditions. By employing such sophisticated techniques, industries can achieve significant reductions in carbon emissions and energy costs, aligning with global sustainability goals.

Moreover, advancements in control mechanisms, such as adaptive sliding mode techniques, further enhance the operational efficiency of bi-directional systems. These innovations ensure smoother operation and optimal performance during demanding tasks, such as those found in mining operations. As industries face mounting pressures related to energy efficiency, the role of bi-directional hydraulic pumps as a critical component in enhancing productivity and sustainability is clearer than ever.

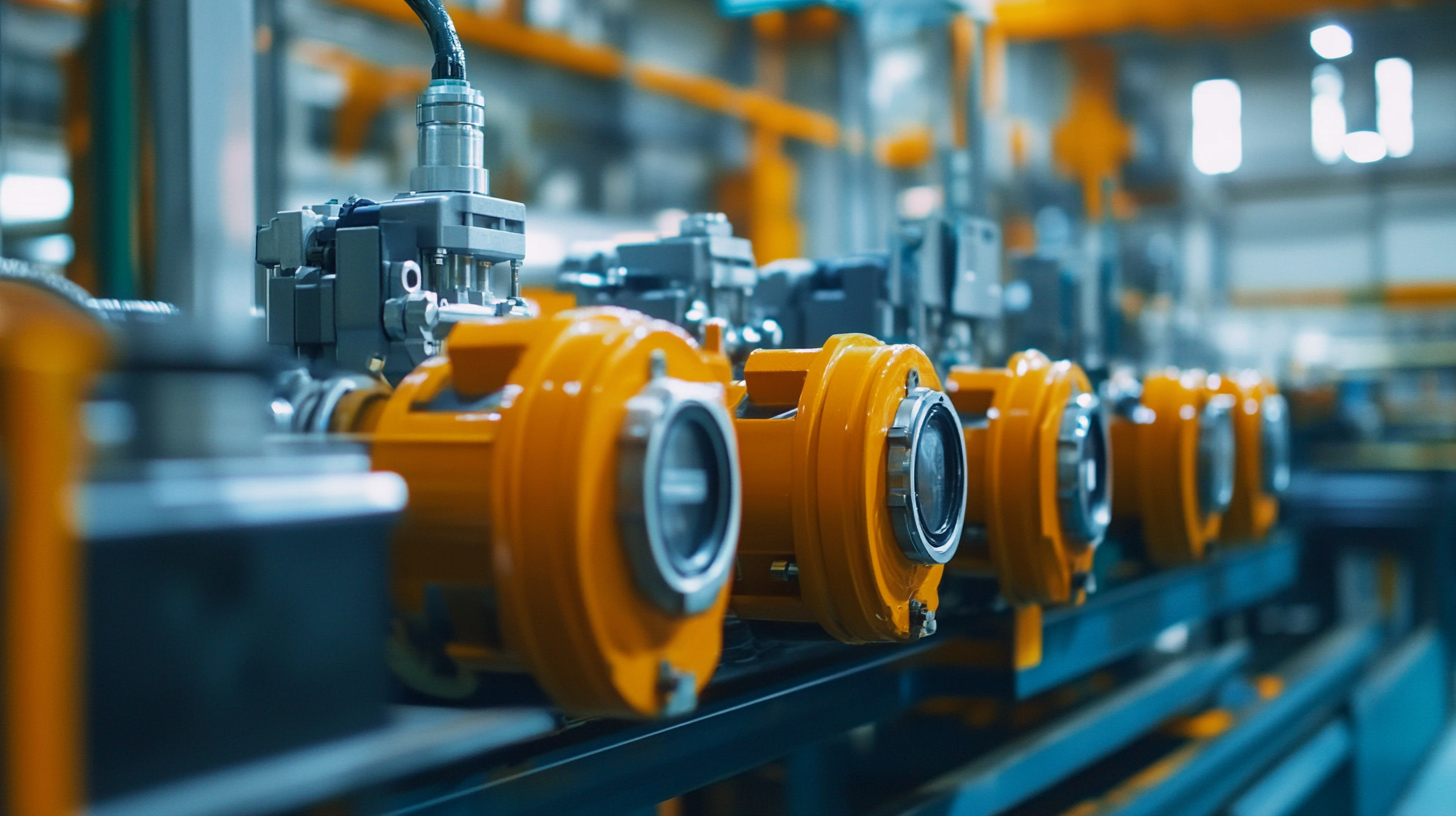

Best Practices for Selecting Bi-Directional Hydraulic Pumps in Supply Chains

When selecting bi-directional hydraulic pumps for supply chains, understanding the unique features and capabilities of these pumps is vital. The first step is to assess the specific application requirements. Different industries may have varying needs in terms of flow rates, pressure capabilities, and installation environments. Evaluating these factors will help narrow down the options and ensure the selected pump can efficiently handle operational demands.

Another best practice is to consider the material and durability of the pump. Bi-directional hydraulic pumps are often exposed to harsh conditions, so selecting a unit made from corrosion-resistant materials can significantly extend the life of the pump. Additionally, understanding the maintenance requirements and service intervals of the pumps can help maintain operational efficiency and minimize downtime.

Compatibility is also crucial when selecting bi-directional hydraulic pumps. It is essential to ensure that the pumps can integrate seamlessly with existing hydraulic systems and components. Collaborating with suppliers who offer expertise in hydraulic systems can provide invaluable insights and ensure a smoother procurement process. By focusing on these best practices, businesses can enhance their supply chain efficiency while avoiding costly errors in their hydraulic pump selections.